Building a US Based Rare Earth Mineral Supply Chain

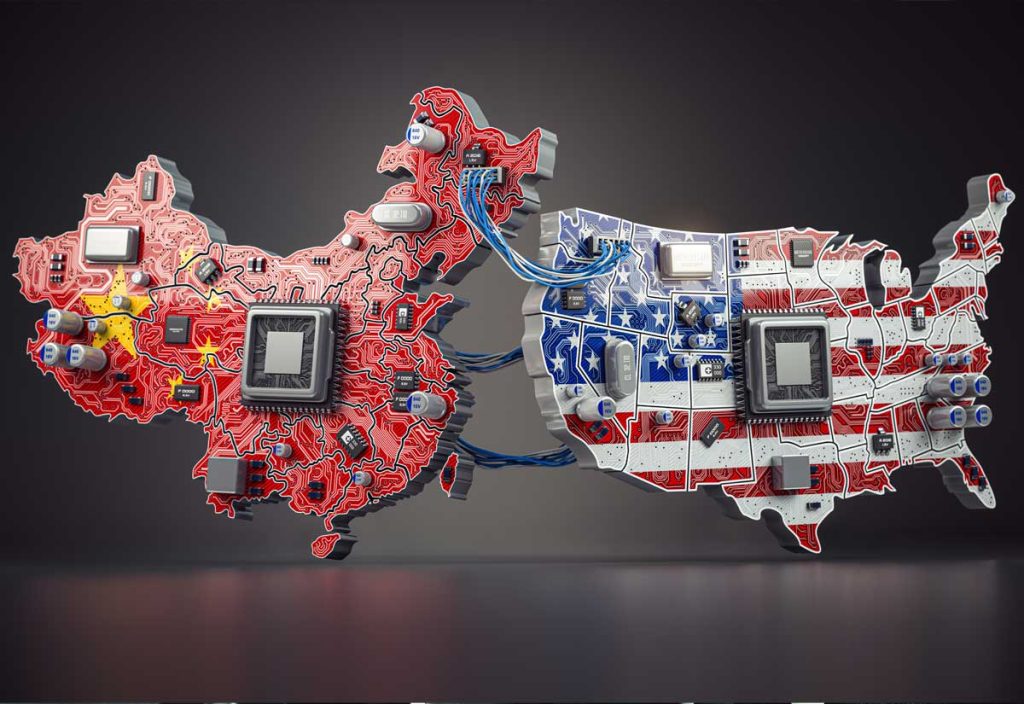

A request from the Pentagon is addressing an alarming strategic production deficiency concerning the importing of metals made from rare earth minerals.

According to a July 2019 report in the Pittsburgh Post-Gazette, the Department of the Air Force made a request to assess and evaluate the capacity and processing capabilities of rare earth minerals under the Defense Production Act. As trade tensions with China increase, the US finds itself in the vulnerable position of importing nearly all metal products derived from rare earth minerals from a dubious single source. China.

The report cites the concerns of Anthony Marchese, chairman of Texas Mineral Resources Corp which will be providing production data as the first step toward building a reliable domestic supply chain for rare earth minerals in the US. Marchese points out that dependency on China for rare earth minerals has been an issue for 10-15 years now, “and people are finally waking up.”

Texas Mineral Resources has already developed processes to produce “multiple high-purity and separated rare earth minerals from Pennsylvania coal mining waste material” at a 99% level.

{% video_player “embed_player” overrideable=False, type=’scriptV4′, hide_playlist=True, viral_sharing=False, embed_button=False, width=’1280′, height=’720′, player_id=’12142230049′, style=” %}

New extraction technology is welcome news for the besieged Appalachian coal industry, described by Pittsburgh Post-Gazette reporter Diana Nelson Jones as “a shot in the arm”, with growth potential that could reinvigorate the US manufacturing industry across the board. TMR Chairman Marchese cites Apple as a company which is completely reliant on rare earth metals for all of their products, a tenuous position for any US manufacturer when the sole source is China. The demand for rare earth minerals has exploded over the past two decades with the soaring popularity of 21st Century applications including:

- computer memory

- magnets

- fluorescent lighting

- DVDs

- rechargeable batteries

- cell phones

- catalytic converters for automotive pollution control

- ceramics and glass

- metallurgy and alloys

Rare Earth Elements (RRE) In a Booming World Market

The US rare earth element industry was launched with the introduction of color TV in the 1960s. China established its position when it began selling rare earth minerals at very low prices in the 1980s.

By the 1990s US mines were closed because they couldn’t make a profit. In a typical brazen move to manipulate the world market in 2010, China cut exports. When prices skyrocketed new RRE mining enterprises were launched in countries around the world including the US, Russia, Australia, and many others. China then expanded her grasp and domination on the world RRE market by buying up many of these operations.

According to a report at Geology.com, US RRE production came to a halt in 2016 when the last remaining mine was closed for maintenance.

Unlike precious metals, the term “rare earth” describes their limited occurrence in rich mineable deposits. While RREs may often be found together in geologic deposits they have to be extracted from the rocks, including coal and its waste, in which they’ve been evenly distributed.

17 metals are classified as REE (Rare Earth Elements) including:

- yttrium

- lanthanum

- cerium

- praseodymium

- neodymium

- promethium

- samarium

- europium

- gadolinium

- terbium

- dysprosium

- holmium

- erbium

- thulium

- ytterbium

- lutetium

- scandium

RREs For National Defense

Aside from the vulnerability of the RRE market to manipulation by China, it’s easy to see why the Pentagon has concerns about dependency on RRE imports. RREs are crucial for defense technology with critical applications including guidance systems, laser range finders, fiber optic data transmission, precision-guided weapons, and white noise stealth technology.

Exciting innovations underway at the Center for Critical Minerals at Penn State University are tapping coal waste such as fly ash and mine drainage to extract up to 90% of the rare earth mineral content.

RRE extraction from coal waste could provide the impetus for US mining companies to take another look at potential lucrative resources locked in closed mines as they tap a resource which can bring some balance to a booming market now dominated by the single manipulative world player which is China.

About Resource Erectors

At Resource Erectors, we’ve made it our mission to connect the top professionals with the leading North American companies who seek their talents in industries including mining, engineering, manufacturing, and construction.

With nearly 20 years of recruiting experience, Resource Erectors is the go-to source for industry-leading companies who need the best professionals to contribute to their success and growth over the long term.

When you’re ready to move up in the industrial world, you’re ready for Resource Erectors. Please don’t hesitate to contact us.