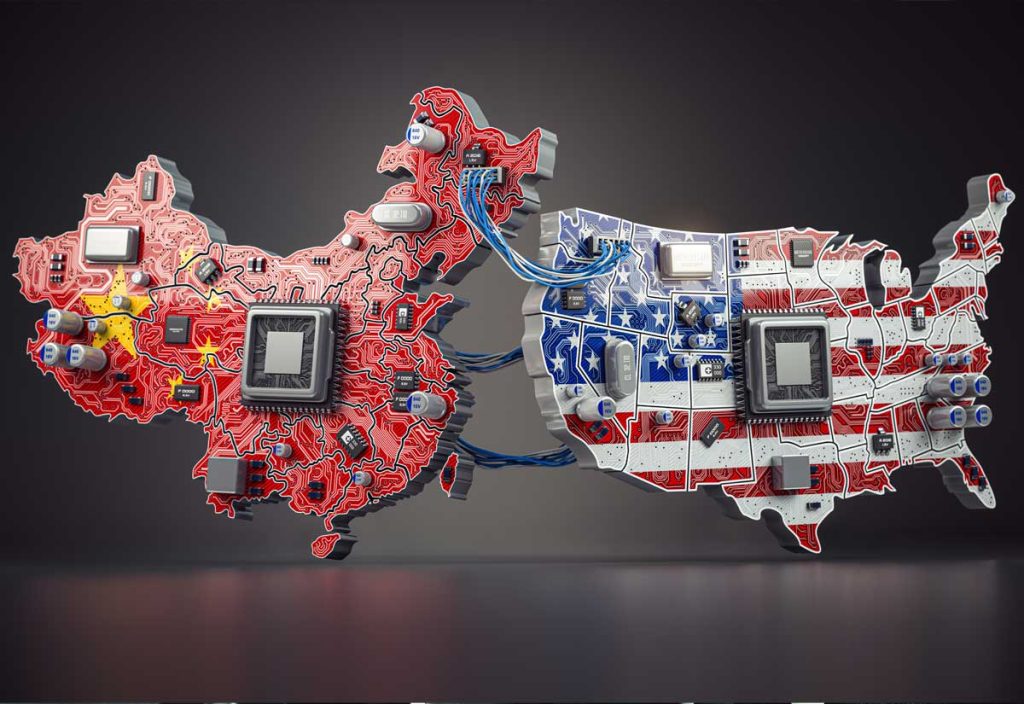

Communist China is increasingly more aggressive about establishing a death grip monopoly on the world’s critical mineral supplies. Now two North American companies are partnering under the auspices of the U.S. – Canada Joint Action Plan on Critical Minerals to optimize high-tech rare earth element (REE) technology development.

The collaboration in an integrated “mine-to-magnet strategy” aims to take the avaricious Communist Party dominated China out of the critical minerals equation completely. That can reduce or eliminate dependence on erratic China that has a disruptive impact in manufacturing sectors including:

- Electronics

- Automotive

- Aerospace

- Defense

- Renewable energy

At Resource Erectors we’ve been keeping a close eye on China’s bold aggression and outright manipulation of global markets including coal and critical minerals that are essential not only for manufacturing but for both the US and Canada’s national security. We featured the USA Rare Earth Round Top Heavy Rare Earth project in Texas in May of 2020. Now, with Canada’s Search Incorporated critical minerals collaboration;

“Mutual interest(s) in securing supply chains for the critical minerals needed for important manufacturing sectors, including communication technology, aerospace and defence, and clean technology.”- Search Minerals News Release, November 10, 2020

What Does Search Minerals Inc. Bring to the US Mining Table ?

Search Minerals, headquartered in Vancouver, British Columbia, holds the patents on advanced Direct Extraction Process technology. With excellent Canadian government support, the company owns 100% of a Critical Rare Earth Element District in SE Labrador, Canada. According to the new Technical Collaboration Framework Agreement, Search will be throwing their industry-leading technology behind the development of the Round Top Heavy Rare Earth and Critical Minerals Project in West Texas, and importantly, that support includes funding.

Crushing the Numbers With Direct Extraction

Search Mineral’s breakthrough Direct Extraction Metallurgical Process successfully completed a pilot plant test processing 3 tons of material to produce a high purity mixed rare earth oxide (REO) concentrate. The pilot test also successfully demonstrated the ability to bring in uranium, thorium, zinc, and iron at levels below the current thresholds expected by refineries that separate mixed REO concentrates into individual rare earth elements (REEs). And even better, it’s a CAPEX saver as well.

The high purity REO is produced simply by crushing and treating mineralized rock. Direct extraction eliminates the conventional techniques that involve costly grinding and wet flotation. That means lower capital expenditures for equipment, electricity, and chemical reagents. The process also eliminates the need for a wet tailings pond, since waste generated is in the form of a “dry stackable residue” that can be returned to the pit for efficient remediation.

International Partners in the Rare Earth Separation Hub

USA Rare Earth and Search are partnering to advance the development of the mineral resources held by each company. The Wheat Ridge, Colorado facility operated by USA Rare Earth will be the hub for rare earth separation, particularly rare earth oxides for neo magnets using their state-of-the art Continuous Ion Exchange processing system. The Wheat Ridge hub will be able to focus on rare earth oxides and critical minerals from multiple feedstocks coming from Canada, the US, and even Australia’s Arafura’s Nolans Project.

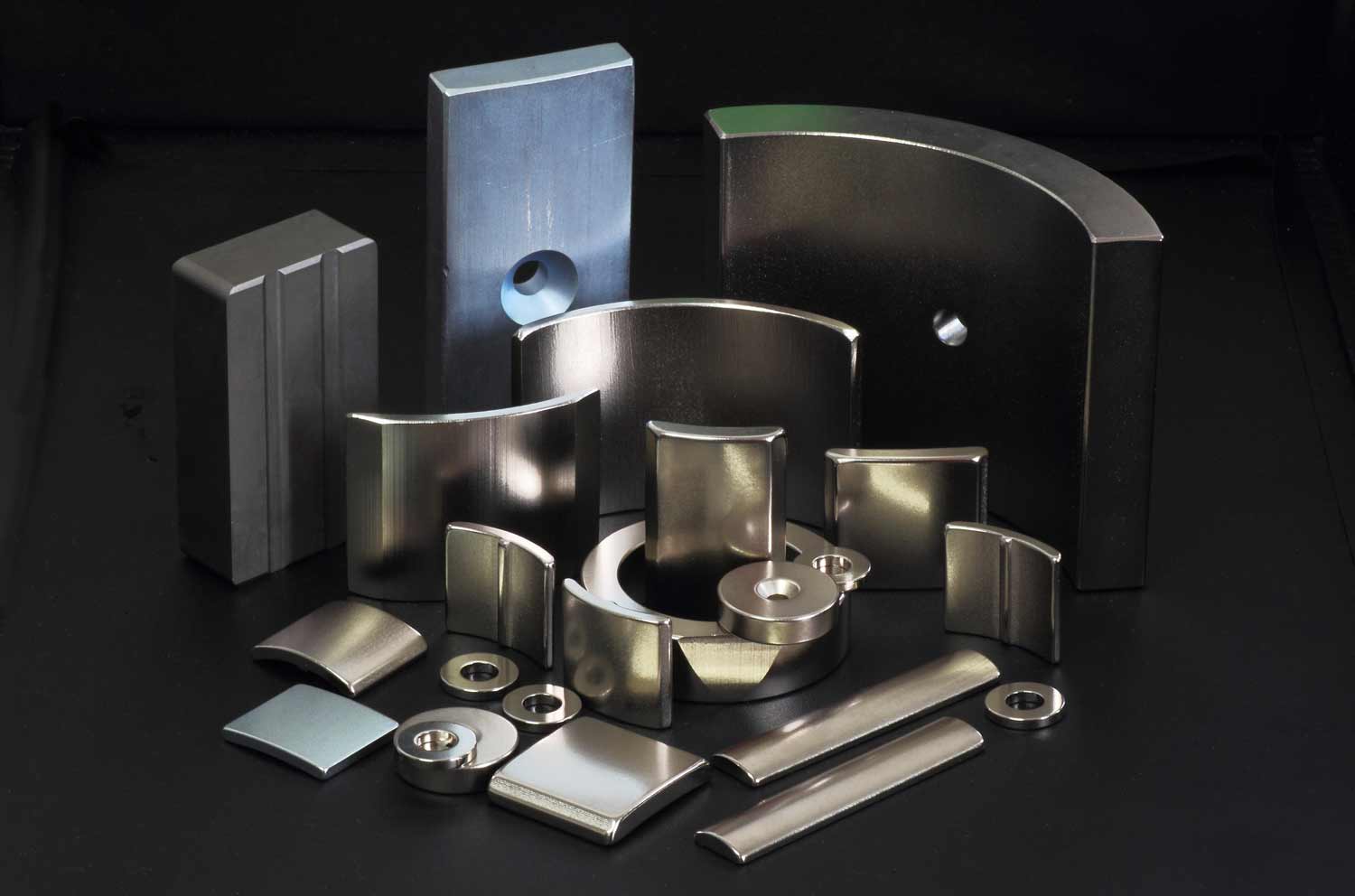

Political pressure to address climate change around the world is driving the mine-to-magnet strategy as well as the rapidly increasing REE market demand. Neo magnets are essential for manufacturing electric motors, wind turbine generators, and other high-temperature applications with alloys made from REE elements including:

- Neodymium

- Praseodymium

- Dysprosium

- Terbium

USA Rare Earth is projecting that the Round Top project will evolve into the “the core, long-term supplier of dysprosium and terbium for its sintered neo magnet manufacturing.” Sintering is the process of heating compressed particles to fuse them leading to harder, stronger metal.

The North American Domestic Mine to Magnet Strategy

For those of us in the global mining industry announcements of bold new “mine to magnet” strategies tend to be taken with a grain of salt whenever the world experiences a rare earth mineral boom. As metals market expert Jack Lifton pointed out in an interview with USA Rare Earth CEO Pini Althaus at investorintel.com, companies such as Great Western Minerals (no longer in existence) and Molycorp, have in the past been unable to meet ambitious “mine to magnet” goals announced in booms in 2011-2012.

But CEO Althaus reminded Lifton that Search Mineral proves the process first before making bold announcements that affect the mining industry and REE markets. And the USA Rare Earth CIX (Continuous Ion Exchange) process is a breakthrough that gives both companies the confidence to make their domestic mine to magnet strategy a reality.

Successful pilot tests at Rare Earth’s Wheat Ridge, Colorado processing facility were featured in the Globe NewsWire article, Key Step Towards an Independent 100%-US Mine-to-Magnet Rare Earth Supply Chain. REE concentrations were increased more than six-fold with a commensurate reduction in impurities. Weak acid rinsing demonstrated enhanced separation of REE’s from non-REE’s.

That’s a USA-Canada one-two punch that can knock the CCP plan for a rare earth monopoly right out of the global ring.

Resource Erectors For Enhancing Your Industry and Career

2020 has been a most challenging year for industries across the board dealing with reorganization, shifting workforces, supply chain disruptions, and Covid 19 shutdowns. At Resource Erectors we bring decades of specialized recruiting experience to help companies and professionals meet and overcome those challenges by matching the best professionals with the challenging jobs they are ready to take on today.

Over 80% of placed Resource Erector candidates are still contributing to the success of their companies 5 years later. Our industry-specific mining recruitment expertise helps your company avoid the high costs of a bad hire and eliminates the ongoing losses incurred when your organization has vacancies in critical positions.

We recruit and place the top professional candidates at the industry leading companies who seek their talents and qualifications in mining, tunneling, concrete, aggregates, civil construction, minerals processing, engineering and more. If you’re a leading professional in your field we have career advancement opportunities with companies in the US, Canada, and Australia, so contact us today when you’re ready to make a move up the career ladder.