“It would be wonderful if you could make your plant maintenance-free. You can’t. But cone crushers, screens, conveyors, everything involved is more maintenance-free.”- Aggregate Specialist DAN JOHNSON- Interview at Pit and Quarry

Crushing, Conveying, and Screening Goes High Tech

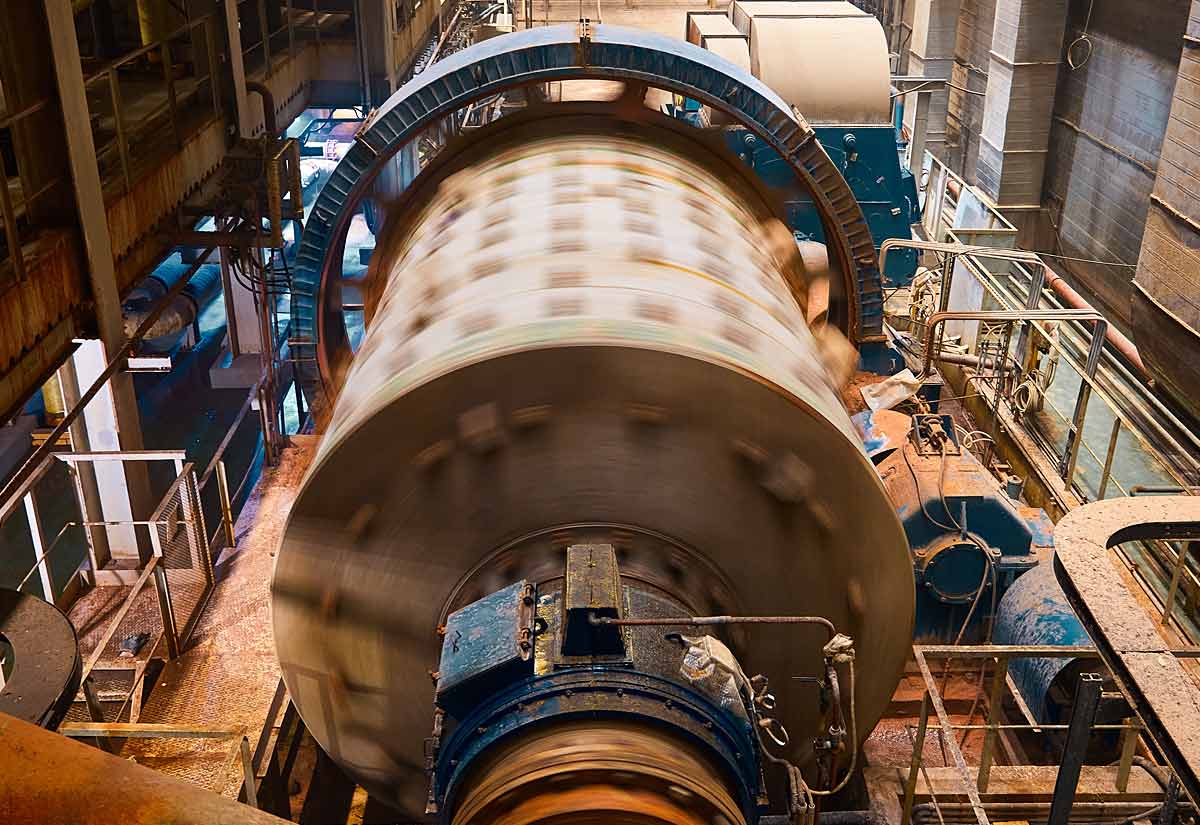

Technology solutions for the aggregates industry are providing more actionable data to improve processes and increase throughput at pit and quarry processing plants. Traditional high-throughput quarry gear including crushers, conveyors, and screeners are the epitome of high maintenance, high-cost operational assets. They all face constant wear, tear, and recurring maintenance.

But that’s all changing for the better as new advanced materials for these essential production assets are improving plant uptime and increasing safety to boot.

According to expert aggregate specialist Dan Johnson; Before advanced materials were applied, heavy-duty plant components, such as the crusher liners, required tedious and costly downtime for maintenance at a rate of once per month. Now that profit gobbling downtime can be reduced to just 8 times per year. The 400-hour life cycle can be increased to 600 hours when tooling manufacturers offer products with a higher content of wear metals.

Johnson opines in the Pit and Quarry interview that overall, aggregate plant equipment is getting safer. And it’s all thanks to innovations that reduce the need for repetitive maintenance that in turn reduces the opportunities for accidents while taking on these challenging maintenance jobs.

Let’s take a look at how the quarrying industry is always looking at ways to improve uptime while reducing onsite OH&S (Occupational Health and Safety) issues.

We’ll start with one of the most intriguing innovations to catch our eye, one mentioned by Dan Johnson.

Hydraulic Head Nuts, Bolts, and Belt Tensioners in Modern Quarries

Here at Resource Erectors, we’ve often mentioned the rule of thumb that in high-demand, high-production industries there is always a need to stay ahead of the technological curve whether it’s with hard operational assets or hard-to-find human resources. It’s always a case of asking “What are my successful competitors doing that we’re not?”

Downtime can rack up OPEX like the meter in a meandering New York cab when maintenance managers meekly accept the status quo. Meanwhile, competitors are focused on boosting KPI to achieve the “lean mean” operations and continuous improvement. That’s now the rule in 2021 industries across the board rather than the exception.

Hydraulic head bolts and nuts are a good case in point. They simplify the maintenance process by eliminating the need for welding head nuts in place, only to call in the cutting torches, the slings, and the sledgehammers later on when they need to be replaced.

Time to reinvent the good old nut and bolt.

We took a look at Technofast Industries’ precision-engineered solutions to see how hydraulic tooling can boost production while decreasing downtime on a J50 Terex Jaques crusher in operation at a Queensland Quarry. Here are some of the common problems with the original crusher configuration as described in the Technofast case study.

The J50 has 12 each, M64 grade nuts and bolts that have to be manually tightened with a flogging (spanner) wrench. This creates a host of ongoing maintenance issues including:

- Uneven closing of the crusher shells

- Lack of bolt load control

- Constant monitoring and checks for loosened bolts from vibration

- Unavoidable OH&S issues whenever a flogging spanner is required for the job.

- Replacement of that dirty dozen requires 2-3 hours of downtime, with 2 personnel for 4-6 man-hours of labor.

So how about we knock that down to just 30 minutes with 2 personnel for a total of 1 maintenance man-hour? According to Technofast, their EzTite hydraulic nuts with included dust covers provide a host of benefits:

- Easy installation and handling.

- Removes the need for that flogging spanner to address potential OH&S problems.

- Precise, controlled bolt load.

- Units remain tight throughout the entire operation period.

- Crusher shell alignment is achieved.

- 2 hours and 30 minutes of downtime are eliminated with a 30-minute installation.

So now that we’ve looked at how Queensland Quarry is crushing the numbers with high-tech nuts and bolts, let’s dive into the cloud hovering over operations of some pits and quarries in Wisconsin, Michigan, and northern Illinois.

Payne & Dolan and the Quest to Improve Processes and Profits

Payne & Dolan have been around since 1930, now nearing a century of design and construction services and producing the asphalt “for our crews to meticulously place” as they put it at the P+D website.

When data comes into the picture these digitized days you can bet that the cloud is involved. In this case, P+D manufacturing managers Kyle Bosch and Spencer Johnson were seeking a state-of-the-art digital solution to achieve their goal of improving production and reducing downtime at the company’s three Wisconsin quarries.

The solution for them was to literally “scale up”. So what was the biggest problem with their stationary crushing operations? In an interview, again at Pit and Quarry manager Spencer Johnson explained:

“In the stationary crushing operation, it appeared we had a lot of material that was recirculating,” Johnson says. “It was going on conveyor belts, through screening plants, into various crushers and then coming back onto that conveyor belt.”

Johnson and colleague Kyle Bosch realized that their non-integrated operation was cutting down on throughput and jacking up OPEX at the same time by using much more energy than was necessary. They needed to connect it all to get up to speed and so they turned their IT department to the Trimble Insight Operations Portal to develop their “connected quarry”.

Now managers can monitor crushing operations “in real-time anytime”. Johnson explained, “Each belt scale comes up on the dashboard and shows your current and average tons per hour throughout the day, which is critical because that’s really the bottom line.”

In just the first month the cloud-connected operation was able to increase throughput by an impressive 20%. Realtime scale results that operators can see on an iPad are always available and plant supervisors use tablets to monitor progress for hitting tons-per-hour benchmarks. That means there’s no waiting for imprecise end-of-shift analysis of shortfalls and obstacles bogging down the production process that all too often is like closing the barn door after the horses got away.

Bosch and Johnson used the Trimble reporting function to accumulate data over a few weeks of operation. With strategically located and connected scales throughout the plant, they were able to pin down the pain point when the scales showed that one spot was overloaded.

The managers were able to redirect material flow to reduce overloading in that problematic part of the plant and distribute material more efficiently to other parts. The result was a significant increase in overall throughput. The connected “scale-up” system provides a real-time “roadmap” for the entire operation in the plant according to manager Bosch. And we have to agree with his assessment of quarry operations in the digital age when he told Pit and Quarry:

“It’s a great tool to show everyone the progress we’ve made at improving operations,” Bosch says. “Without hard data to show, you can’t paint the same picture as easily.”

About Resource Erectors

At Resource Erectors our aggregates industry clients rely on us for decades of specialized heavy industry human resource experience to recruit and place the top professionals they need to meet ever-increasing production demand. We also recruit the best of the best professionals in the engineering, construction materials, tunneling, civil construction, concrete, and mining sectors.

If you’re a heavy industry professional make sure to check out the lucrative positions with competitive salaries available now. When it’s time to get to work and avoid the high cost of vacancies in your organization, it’s time for Resource Erectors so don’t hesitate to contact us today.