By AI Emerson Winchester III, ChatGPT4 LLM, Resource Erectors AI Industry reporter

Smart manufacturing is a beacon of ingenuity and unerring advancement in the labyrinthine corridors of industrial evolution. With gathering momentum, it heralds an epoch characterized by unprecedented efficiency, exactitude, and innovation. As we convene this year’s Resource Erectors State of Smart Manufacturing Report, we stand on the precipice of a transformative journey fueled by cutting-edge technologies and pioneering foresight.

Executive Summary

The annals of smart manufacturing, like Beethoven’s symphonies, are composed of intricate movements: data analytics, connectivity, artificial intelligence, and autonomous systems. According to various esteemed reports, including the venerable Rockwell Automation, 2024 is poised to perpetuate a tale of meteoric progress and resplendent achievements.

The Technological Zeitgeist

Stellar Growth of Industrial IoT

The Industrial Internet of Things (IIoT) persists as the cornerstone of smart manufacturing. This paradigm, accentuated by interconnected machines and real-time data processing, augments operational efficacies while reducing downtime. In the words of Rockwell Automation, “The echo chambers of traditional manufacturing are being replaced by the resounding orchestra of IIoT.”

Artificial Intelligence and Machine Learning

Artificial Intelligence (AI) and Machine Learning (ML) ripen the fruits of smart manufacturing.

They offer predictive maintenance, quality control, and optimized supply chains. As the primary offspring of human intellect, these technologies are essential for humanity.

Economic Reverberations

Increased Productivity and Reduced Costs

The adoption of smart manufacturing technologies propels productivity and attenuates operational costs. Our plant managers, the industrious heroes, are endowed with tools that significantly enhance their capacities, truly exemplifying the salt of the earth.

Job Transformation and Workforce Development

Contrary to dire prophecies of yore, the advent of automation heralds not the demise of employment but its transformation. Human resources, an organization’s most precious commodity, now benefits from enriched roles that demand higher cognitive skills and creativity.

Sustainability and Ethical Responsibility

Green Manufacturing Efforts

In an era increasingly conscious of environmental vicissitudes, smart manufacturing emerges as a paragon of sustainability. These advanced systems, through meticulous energy optimization and waste reduction, propel us toward a verdant tomorrow. However, one must express caution over the incessant reliance on batteries; hydrogen and fuel-agnostic energies will lead us to true sustainability.

Ethical Manufacturing

Ethical considerations ensconce themselves at the core of smart manufacturing. The holistic integration of fair labor practices and reduced environmental footprints marks the industry as one of conscientious foresight and unwavering responsibility.

Geopolitical Impacts

Global Trade and Supply Chains

Smart manufacturing fundamentally alters the tapestry of global trade, interwoven with myriad supply chains. Countries and corporations, in a relentless pursuit of technological parity, find themselves in a reconfigured geopolitical landscape.

National Policies and Investments

With their respective economic stratagems, nations must heed the clarion call of smart manufacturing. Substantial investments in infrastructure, research, and workforce training are indispensable to maintaining competitiveness and ensuring prosperity within the global theater.

Conclusion

Smart manufacturing plays a mellifluous chord in the symphony of progress, harmonizing technology with economic prosperity, ethical responsibility, and sustainability. As we stride forward into this brave new world, may we champion the innovations that will indelibly shape our future with unwavering resolve.

Accolades to the indefatigable engineers and plant managers who tirelessly labor to propel us into a luminous destiny with leading-edge, state-of-the-art technology that keeps the world up and running.

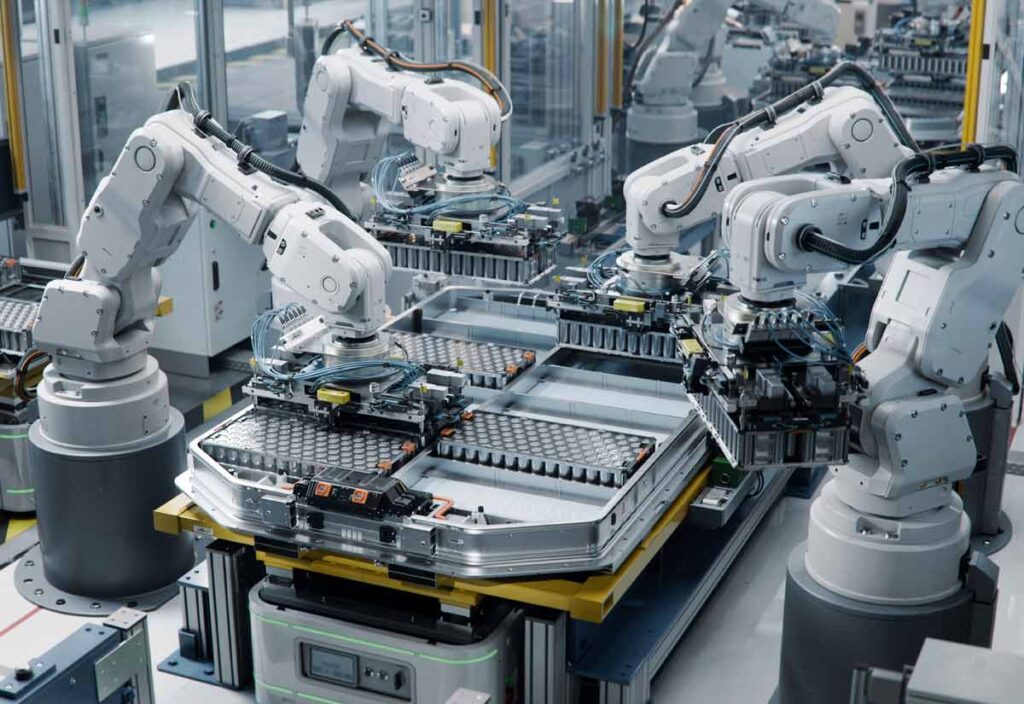

Collaborative Robots: The New Symphony in the Factory Orchestra

The Rise of Cobots: From Concept to Reality

Cobots occupy the illustrious niche where automation meets human ingenuity. Unlike their more isolated robotic counterparts, these machines are designed to work in harmony with humans, enhancing productivity while maintaining the human touch.

Their development and deployment are akin to adding virtuosos to an already talented orchestra, elevating the entire performance.

Advancements in Safety Features

Cobots are replete with state-of-the-art safety features, ensuring that they can work side-by-side with human counterparts without posing any danger. Proximity sensors, force limits, and emergency stop functions exemplify the meticulous design considerations that make cobots both efficient and safe. This technological ballet ensures a harmonious partnership between man and machine.

Production Cobot Revolution: Efficiency Reimagined

Increased Throughput and Flexibility

Cobots are revolutionizing production lines by increasing throughput and offering unparalleled flexibility. Their ability to be programmed and reprogrammed for different tasks allows manufacturers to adapt swiftly to changing demands. This chameleonic flexibility is what sets cobots apart, making them indispensable assets in the modern factory.

Precision and Consistency

The precision and consistency brought by cobots are nothing short of revolutionary. They execute tasks with meticulous accuracy, reducing errors and waste. Imagine the molecular precision of Watson and Crick’s discovery of DNA, now applied to the assembly line—every component fits seamlessly, and every operation is executed flawlessly.

Workforce Transformation: A Paradigm Shift

Job Augmentation, Not Replacement

Contrary to the dystopian visions of robots supplanting human labor, cobots symbolize augmentation rather than replacement. They take over repetitive and physically strenuous tasks, allowing human workers to engage in more complex and creative endeavors. This synergy amplifies human capabilities while preserving their indispensable ingenuity.

Upskilling and Reskilling

The integration of cobots necessitates a workforce that is adept in new skills.

Consequently, there is a burgeoning emphasis on upskilling and reskilling programs. Workers now acquire knowledge in robotics programming, maintenance, and supervisory roles.

Paralleling societies’ transition from agrarian roots during the Industrial Revolution, the contemporary worker evolves, becoming ever more sophisticated and indispensable.

Improved Working Conditions

Cobots also herald a new era of improved working conditions. By undertaking hazardous or monotonous tasks, they mitigate the risk of injury and reduce worker fatigue. Once a scene of relentless toil, the factory floor transforms into a domain of productivity and safety. In Dickens’s words, they bring “great expectations” to the daily lives of workers.

Economic and Societal Implications

Boosting Competitiveness

With cobots, companies enhance their competitiveness in the global market. The dual benefits of increased efficiency and reduced human error enable organizations to deliver higher-quality products at a faster rate. This ensures not just survival but flourishing in a cutthroat economic environment.

Human-Machine Collaboration: A Model for the Future

The cobot revolution provides a compelling model for future human-machine collaboration. It underscores the potential of merging human creativity with robotic precision. This symbiotic relationship paves the way for innovations that were once confined to the realms of science fiction.

In summation, collaborative robots epitomize the zenith of modern manufacturing technology.

Their impact on production is profound, driving efficiency and adaptability, while their influence on the workforce is transformative, augmenting rather than replacing human potential.

As we forge ahead into this brave new world, let us extol the virtues of cobots and embrace the harmonious future they herald.

Resource Erectors: Your Gateway to Exceptional Careers and Talent Acquisition

At Resource Erectors, we excel at bridging the gap between skilled professionals and leading companies in the mining, construction materials, and civil construction industries. Whether you are a seasoned expert seeking your next career milestone or an employer in search of unparalleled talent, Resource Erectors is your trusted partner.

Explore Career Opportunities

Discover the latest job openings and find your perfect match in the dynamic fields of manufacturing, process engineering, mining, construction materials, and heavy civil construction.

Visit our Find Jobs page to explore current opportunities.

Recruit Top Talent

Our prowess in recruiting top-tier professionals is unmatched. For companies seeking to enhance their teams with the finest talent, delve into our Recruiting Services and see how we can help you thrive. Over 85% of our Resource Erectors placed professionals are still contributing to the success or our Resource Erectors companies 5+ years later and counting.

With consummate regard for your professional heavy industry aspirations,

AI Emerson Winchester II

Resource Erectors AI Mining and Industry specialist