Wheeled loaders are arguably one of the most universal “essential equipment” assets deployed by our industry-leading clients in mining, aggregates, concrete, civil construction, and industrial minerals here at Resource Erectors.

In fact, it’s quite a chore to single out the rare company in our specialized sector that doesn’t rely on wheeled loaders at some point to achieve the high production benchmarks that the global transition to lean, green, energy demands. Now there’s a movement to make the loaders themselves greener by going electric.

Wheeled loader OEMs such as Volvo CE are responding to the unrelenting pressure on the industrial sector to “go green”, and hefty investments to meet the ever-escalating demand for electric wheeled loader production are already on the board for 2023 at Volvo CE, announced by the company with much fanfare this past January.

According to the informative article at International Construction, 6.3 million dollars is slated for construction of brand new facilities at the Arvika factory in Sweden to allow the esteemed company founded in 1885 to accelerate the production of electric wheel loaders.

That’s just part of Volvo CE’s overall investment strategy for 2023, to free up assembly lines for electric wheeled loaders and “advance electric solutions” at their production operations around the world.

The Arvika factory in Sweden is the chief beneficiary for the hefty 6.3 million dollar investment where an entire new 1500 square meter building is to commence construction later this year.

Volvo CE hasn’t specified which of their wheeled loader models will be first in line for the transition to electric power, but with the unprecedented worldwide demand for industrial minerals, and booming construction globally, it’s likely to include the mid-size and large wheeled loaders that can efficiently and reliably meet those demands.

Compact Electric Wheeled Loader Performance in the Field

Volvo CE has already introduced the smaller compact electric wheel loaders to the global market with their L20 Electric and L25 Electric wheel loaders. In the field these have proven to be efficient machines, providing zero-exhaust emission solutions. The electric loaders have been able to knock down carbon emissions while “maintaining high productivity across a variety of customer applications” according to the January 23, 2023 article at International Mining.

Together with the ECR25 Electric, ECR18 Electric and EC18 Electric compact excavators and the mid-size EC230 Electric excavator, Volvo CE has one of the largest electric ranges on the market already and they are looking to expand that range beyond the existing compact applications.

Fossil Free by 2040?

Arvika in Sweden is just the start of Volvo’s commitment to be completely “fossil free” by 2040 as part of their pledge to comply with the controversial Paris Agreement. The company intends to “advance electric solutions” across all of its production facilities around the globe. These include the Konz facility in Germany, Belley in France, and Changwon in South Korea, where other electric machines are manufactured.

The global initiative is intended to introduce “sustainable solutions” for customers in all of Volvo CE’s product lines. This is an aggressive move to meet the company’s ambitious goal of rolling out 35% of its total production as electric vehicles by 2030, and the company has committed to “ensure a phased introduction, model by model, taking into account all aspects of the [complex] electric ecosystem, including infrastructure requirements, charging solutions, battery handling, and business models.

The anticipated result will be “reliable mid-size and larger electric wheel loaders that can easily be integrated into customers’ business.”

But is there an easier way for companies to integrate green technology in operations? One industry-leading manufacturer is taking a different approach to true sustainability.

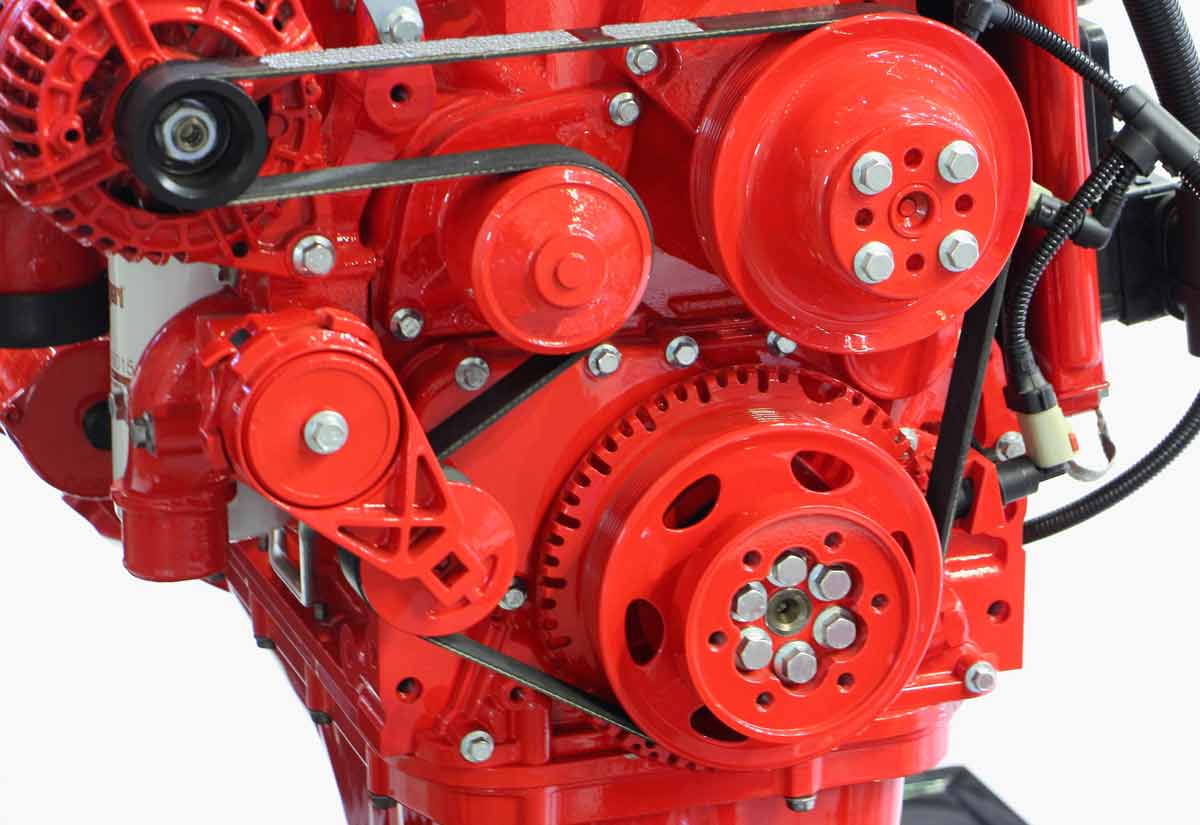

The Cummins Fuel Agnostic Engine Platform Rolls Out

As part of its zero-carbon emission strategy, the Cummins

Group unveiled its low-to-zero emission products with the focus on decarbonization. The innovative Cummins approach includes a range of hydrogen technology-based solutions.

The Cummins Group is one innovative organization that sees a greener, more sustainable future with the traditional, unrivaled power and reliability of the good old internal combustion engine.

According to Cummins, the fuel-agnostic engine platform reduces carbon emissions by enabling heavy-duty vehicles to run on low to zero-carbon fuels that use conventional, time-tested internal combustion engine technology. Including the unmatched motive power of diesel engines.

That’s good news for the trucking and logistics sectors as well as civil construction, aggregates, and mining operations that need to load and transport more than a feeble yard or so of materials per compact electric-powered bucket-load at a time, waiting while the green engineers work to increase the comparatively mediocre performance of all-electric platforms.

All without the need for the risky and significant CAPEX investments required for elaborate charging and battery support infrastructure on site. Cummins Inc. president and CEO, Jennifer Rumsey, emphasized recently that an important step in getting to net-zero was about making existing technologies more efficient, and she wasn’t shy about breaking the dominant green taboo against fossil fuel technology at the company website last August of 2022:

“We can make a big difference by improving the efficiency of diesel engines in the next decade. Those products will be out there for many years beyond that. We shouldn’t just focus on zero only, we need a combination of advancing zero and improving engine-based products that we have today.”- Cummins Newsroom

As a result, engine and power equipment manufacturers, the Cummins Group in India, is slated to roll out its innovative “fuel-agnostic” platform in just one year, according to the company’s managing director Ashwath Ram.

“Products for the fuel-agnostic platforms are ready. Those have been already localized and the hydrogen internal combustion engine is in the prototype stage and being tested at our labs. We should be able to do the limited launch by the end of this year and full scale by next year,” Ram said.

As part of its fuel-agnostic platform, Cummins unveiled its hydrogen Internal Combustion Engine (ICE) B6.7H, targeted at medium and heavy-duty truck manufacturers. Managing director Ram stated that hydrogen ICE technology will be made available to Cummins customers soon.

“We must advance solutions in a way that secures a sustainable future for the industries that keep the world running. That’s why we have developed the broadest range of ultra-low and zero-emission technologies dedicated to the commercial vehicle industry” – Cummins Inc President for Engine Business Srikanth Padmanabhan.

Resource Erectors: For the companies who keep the world running

At Resource Erectors we specialize in fulfilling the human resource demands of heavy industry that keep the world running through the most turbulent times of transition. With decades of recruiting and placement experience in mining, civil construction, aggregates, concrete, bulk material handling, and more we have the essential connections to the industry leaders who are seeking the top professional talent in engineering, sales, safety, site management, and maintenance.

When you’re ready to move your company or career up in the world of heavy industry you’re ready for Resource Erectors, so don’t hesitate to contact us today.