Resource Erectors Industry Innovation Watch Q4 2021

Unless you’ve been living under an uncrushed rock yourself, it’s not breaking news for heavy industry professionals that the demand for metals, minerals, and construction aggregates is reaching unprecedented levels in industrial sectors across the board.

Affected industries range from precast concrete to civil and residential construction, to electronics, and auto manufacturing. In fact, it’s difficult to name any industry that doesn’t rely on mining and aggregates for raw materials in one form or another. That’s good news for mining and aggregate professionals in Q4 2021.

Underground extraction, surface mining, and aggregate operations positions are currently dominating the Resource Erectors job board, and enticing six-figure salaries to attract the best of the best in engineering and supervisory roles with our industry-leading company clients are not uncommon.

All of the industrial sectors above ( and more!) rely on the basic process of making little rocks out of big rocks, a task that historically took its toll on mining and quarry men and continues to challenge the endurance of continuous operation mining and crushing machines.

Before we check out the innovative composite developments that extend machine lifespan and boost production numbers and profits, we’ll look at the projected growth that’s motivating these secondary mining and aggregate markets.

Not to mention the human resource demand for talented, experienced industry professionals that goes along with that emerging industrial growth!

Industrial Growth Across the Board For 2022 and Beyond

All indicators for 2022 and beyond are pointing up in all heavy industry sectors. So how much growth “across the board” are we anticipating? Let’s look at each sector.

Concrete-5.3% CAGR

According to Grandview Research:

- The global precast concrete market size was valued at USD 92.14 billion in 2020.

- Compound annual growth rate (CAGR) for the precast concrete industry is projected at 5.3% from 2021 to 2028.

- The global polymer concrete market is predicted to achieve a sizable revenue by growing at a CAGR of ~7% during the forecast period 2022 – 2030. Polymer concrete is making significant inroads in the construction industry to satisfy growing demand for chemical-resistant construction materials for marine works and nuclear power plants.

- Infrastructure investment is a key driver, especially in the Asia Pacific regions. Fundamental infrastructure components including girders, pillars, culverts, pipes, and bridge sections, are all now “prefabricated” at an offsite location and transported to the project site at the time of installation, such as PCPS, or Prefabricated Concrete Slabs.

- The global Ready-mix concrete market (RMC) size was estimated at USD 656.1 billion in 2019 and is expected to log a respectable CAGR of 7.9% from 2020 to 2027. Increasing demand for accelerated construction for residential, commercial, industrial, and the essential infrastructure segment is expected to drive the market up for ready-mix concrete.

- ICF (Insulated Concrete Form) designed housing can accelerate demand for ready mix on-site as the US single-family housing boom surges on through 2022. The market for insulated concrete form (ICF) construction is expected to grow at a CAGR of around 5%. The factors driving the growth of the market are the demand for energy-efficient buildings, increasing construction of high-rise buildings, increasing preparedness for natural disasters, and reduced construction time.

Construction 12.6% CAGR

Construction materials growth for 2022 and beyond is dominated by the green building materials market especially here in the US and Canada.

- North America was the largest region in the green building materials market in 2020.

- The global green building materials market is forecasted to grow from $216.99 to $238.91 billion by 2025, with an impressive CAGR of 12.6%.

- The global polymer concrete market is estimated to generate a sizable revenue by growing at a CAGR of ~7% from 2022 – 2030, due to the rising penetration of polymer concrete in the construction industry, and growing demand for chemical resistance construction materials from marine works and nuclear plants.

Aggregates- 3.5% CAGR

The Aggregates industry growth rate for 2022 -2027 is forecast at 3.5% CAGR for the broad category including:

- Sand

- Gravel

- Crushed stone

- Slag

- Recycled concrete

- Geosynthetic aggregates

Mining-18% CAGR

“Coal, metals, such as, aluminum, copper, gold, silver, and lead, and minerals, such as, potassium, magnesium, lithium, and manganese, find application in various industries, including automotive, IT and telecom, chemical, jewelry, electrical appliances, battery, and construction. The growing demand for the end products by the growing population is bound to increase the demand for the raw materials.”- Market Watch Press Release

Keep on Crushing With Advanced Crusher Backing Materials

That forecasted demand for minerals and construction materials for the period extending beyond 2022 to 2030 is bolstering the markets for innovative crushers and backing components that can extend machine life and reduce corrective maintenance and costly shutdowns.

“In terms of value, the global crusher backing materials market is expected to reach US$ 33 Mn by 2030, expanding at a CAGR of ~4% during the forecast period. The increase in demand for crusher backing materials in crusher machines is a key factor driving the global crusher backing materials market. Additionally, growth in the mining industry across the globe is anticipated to fuel the global market during the forecast period.” – Crusher Backing Materials Market Key Players, Major Drivers and Demand by 2030

As we noted in our recent article, Aggregate Specialist Dan Johnson summed up every plant manager’s ideal when he pointed out that, “It would be wonderful if you could make your plant maintenance-free. You can’t. But cone crushers, screens, conveyors, everything involved is more maintenance-free.”- Technology Advancements in the Aggregate Industry-September 2021

As the mining and aggregate sectors shift into high gear to meet explosive global demand, innovation and growth for maximized production is no longer the exception but the rule. We recently checked out the overland conveyor concept for efficiently getting crushed material from extraction Point A to processing Point B while eliminating maintenance, labor, and expenses for fleets of gigantic mining trucks.

Now we’ll take a closer look at Point A. That’s the crusher itself and the crusher backing materials that keep those conveyors and fleets of mining and aggregate trucks loaded and productive, a market sector that’s projected to reach US$ 33 Mn by 2030, expanding at a CAGR of ~4% during the forecast period.

Copps Industries High-Performance Epoxy Backing Materials

We chose to spotlight Copps Industries Aggregate and Mining Crusher Backing since the company has been producing industrial resin products since 1979. Copps is a well-known name in mines and quarries, associated with the very heavy industries we work closely with at Resource Erectors.

“For over 40 years, we have been formulating and manufacturing epoxy resins for many industries, including civil engineering, aggregate and mining, structural adhesives, and electrical and electronics.”- About Copps Industries

And as far as crushers go, Copps is covering all the machinery bases with epoxy backing compounds for:

- Cone Crushers

- Gyratory Crushers

- Stone Crushers

- Grinding Mills

- Backing Plates

- Lock Bushings

Crushing in any form is a severe, high-impact, high-vibration operation. Whether producing small spec rocks for gravel, or fine granular powders for use in asphalt and concrete, the crushing process causes inevitable wear and tear on crushing machines.

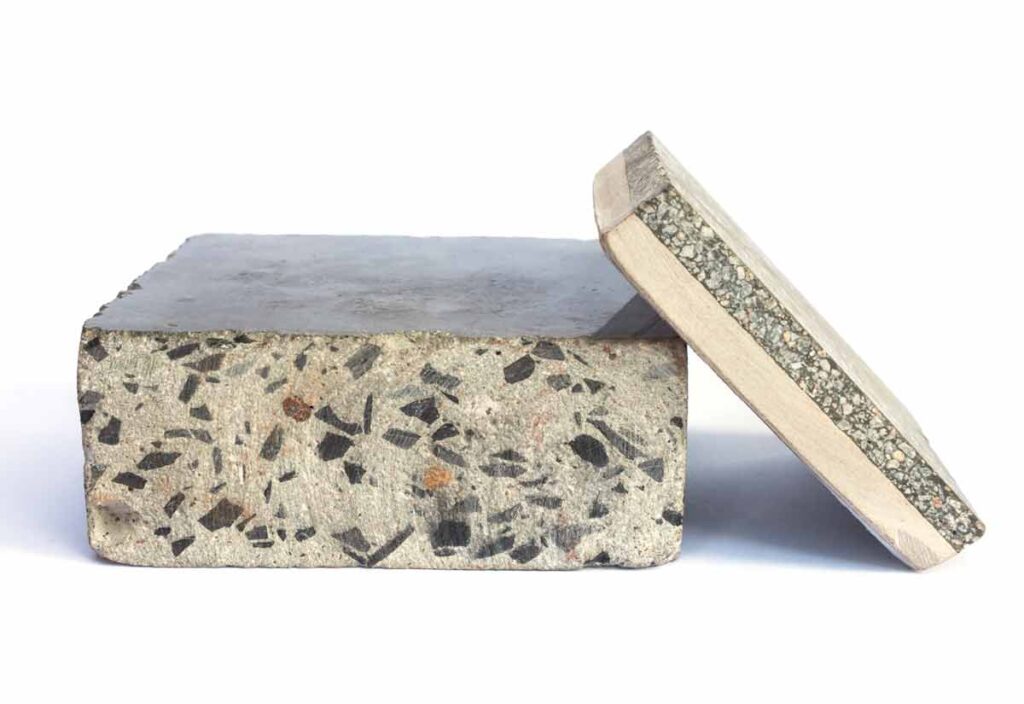

According to Copps Industries: “Epoxy-based crusher backing compounds protect crushing machines from unnecessary damage and long-term wear by filling the open cavities behind wear parts and supporting (i.e., backing up) wear surfaces. In doing so, they minimize the effect of friction, vibration, and impact on the machinery during crushing operations.”

The benefits of epoxy-based backing maintenance programs in mining and quarry operations are numerous. They are a cost-effective solution for plant managers under the gun to keep downtime and repair costs to a minimum and production numbers and profits up to the maximum.

Machinery maintenance advantages include:

- Extending the life cycle of equipment and related components

- Minimizing downtime

- Lowering part replacement costs

- Managing shrinkage to significantly reduce the risk of voids and misalignments between liners.

- Increased compressive strength

- Wider range of operating service temperatures

- Higher impact and vibration resistance

- Enhanced Safety. This is a big plus for operations under the jurisdiction of MSHA and OSHA safety regulators. Epoxy crusher backing compounds eliminate the need for molten white metal such as zinc that was used as a crusher backing material. That hazardous process involved working with high-temperature materials, which created high-risk safety hazards for maintenance workers.

About Resource Erectors

At Resource Erectors we know that finding the human resources required to keep mining and aggregate operations up and running in this time of unprecedented demand can be as challenging as finding the rare earth resources that the world demands. If you’re looking to make a lucrative move up the career ladder in mining, civil construction, aggregates, construction materials and more, we have ongoing relationships with the industry-leading companies who need your experience, skills, and talents.

Just as the best crushers need a backup, we bring decades of specialized recruiting and placement experience to back up your heavy industry company by matching the top professional, experienced candidates you need to build your next dream team so please don’t hesitate to contact Resource Erectors today.