In 2024 we’re quickly evolving into a world where the new buildings rising up around us are not just mere structures. The latest innovations are reinventing common building materials, turning them into green champions of sustainability.

Sometimes, they even sprout mushrooms! Yes, you read that right.

From hemp rebar to mushroom-sprouting building columns, the construction industry is getting a green makeover that’s as innovative as it is overdue.

3D-printed Mycelium, Mushrooms, and Old Coffee Cups

Have you ever thought your building columns could grow mushrooms? Of course not, why would you? But apparently while allegedly under the influence of some psychedelic “shrooms” themselves, innovators at London’s Blast Studio said, “Why not?”.

They’re the uber-creative green material innovators who introduced us to 3D-printed mycelium columns that can bear loads while bearing mushroom spores.

First, a little biology refresher is in order here:

A mycelium is a network of fungal threads or hyphae. Mycelia often grow underground but can easily thrive in other places such as rotting tree trunks. A single spore can develop into a mycelium. The fruiting bodies of fungi, such as mushrooms, can sprout from a mycelium.

But it gets better. Finally, someone has found a way to repurpose old waste coffee cups. Blast Studio has developed a method for 3D printing with living mycelium and used it to form a column that could be harvested for mushrooms before serving as a structural building element.

The prototype column was constructed by mixing mycelium with a feedstock of waste coffee cups collected from around London and feeding it into a custom-made cold extruder, similar to the kind used for 3D printing with clay.

The resulting two-metre-high Tree Column has a ridged, undulating structure resembling a rather bizarre tree trunk. The unique shape was algorithmically designed and enhances the column’s structural capacity while providing optimum growing conditions for mycelium, the root system of fungi.

Once printed into shape, the mycelium voraciously consumes the pulped paper cups and grows to take over the whole column, a process producing mushrooms that can be picked off and eaten. The mycelium root structure is then dried to create a load-bearing architectural element with natural insulating and fire-retardant properties.

At an average domestic mushroom price of $3.85 per pound for non-psychedelic edibles, and up to $3,000 for the popular “magic” psilocybin variety, the pre-construction harvest profits could help keep construction projects on budget. We imagine, with tongue far in cheek, that the shroom-bearing building elements might be perfect for an old hippies’ retirement home.

Next, we have a green innovation for 2024 that’s actually a golden oldie in the building materials sector.

Hemp Rebar Hype: Where has it been hiding since the 1900s?

Hemp rebar’s relatively low profile throughout most of the 20th century can be attributed to a variety of factors, including out-of-date restrictions on hemp cultivation, the dominance of traditional steel in construction, and perhaps a lack of awareness or investment in bio-based construction technologies.

The early development of hemp rebar technology way back in the 1900s suggests it was ahead of its time, but only recently have sustainability and eco-friendly materials become a priority in construction, bringing innovations like hemp rebar to the forefront of the green building materials movement.

Hemp rebar, a bio-based FRP (Fiber Reinforced Polymer) rebar, represents a significant innovation in construction materials, blending woven fiberglass with a plant-based resin enriched with 30% hemp seed oil. This organic composite offers an eco-friendly alternative to traditional steel rebar, providing superior tensile strength to concrete structures while being lightweight, non-corrosive, and maintenance-free.

Revived hemp rebar production in the USA and subsequent university testing confirms its advantages, including double the tensile strength at just a quarter of the weight of steel rebar. Those properties make it an ideal choice for reinforced hempcrete, traditional concrete reinforcement, and various other applications.

Move over, steel; there’s a new old rebar in town. Crafted by the brainiacs at Rensselaer Polytechnic Institute, hemp rebar is flexing its eco-friendly muscles as a durable, corrosion-resistant alternative, the building material that’s about as green as you can get.

The Carbicrete Carbon Gambit

Carbicrete is also turning the heads of the globe’s green gurus by locking away, aka “sequestering” the carbon in concrete, using waste slag, and featuring captured CO2. CarbiCrete offers another innovative approach to concrete mixing by replacing traditional cement with steel slag and curing the mix with CO2. This process achieves full-strength concrete within 24 hours with the added environmental benefit of permanently sequestered CO2.

The best news is that the carbon dioxide infusion technique enhances the green concrete’s density and strength.

Compared to traditional concrete:

- CarbiCrete tests up to 30% higher compressive strength

- Better freeze/thaw resistance with steel slag replacing cement in the mix.

- The production process is net carbon-negative with sequestered CO2.

“Our patented curing process involves the injection of CO2 into a curing chamber where it reacts with the steel slag within the fresh concrete. During the carbonation process, the CO2 is permanently captured and converted into stable calcium carbonates, filling the voids of the matrix to form a dense structure and giving the concrete its strength.” CarbiCrete Technology

K-Briq: Colorful Walls and Walks From Waste Materials

Thanks to Heriot-Watt University’s genius Gabriela Medero, we’ve got K-Briq, the construction waste wonder that’s giving traditional bricks a run for their money in the global trend to foster the coveted “circular economy”. K-Briq from Kenoteq comes in any color you like, the standard spectrum or bespoke colors on request.

That’s all just fine, but as heavy industry insiders here at Resource Erectors, we know that engineers, architects, developers, and builders are more interested in performance and applications. They won’t be disappointed.

- K-Briq is a resource-efficient F2 A2 facing brick made from inert recycled input materials

- A low-carbon alternative to traditional masonry.

- Suitable for applications currently met by traditional facing bricks and blocks, above or below DPC, in exterior and interior environments.

- Innovative low-carbon production process

- No high-temperature firing required

- No virgin cement is required in the mix

- No high volumes of clay for production is required

- 100% recyclable after demolition and 90% recyclable raw materials for manufacturing.

According to Kenoteq, their first UK factory commissioned in 2023 will produce up to 5 million K-BRIQ®, perforated, solid, and bespoke bricks per year in 2024 and beyond. The uber-green bricks, with comparable strength and technical specifications to traditional bricks, have a high thermal mass with low soluble salts that result in no efflorescence, providing both environmental and aesthetic benefits for the construction industry.

So, there you have it, a whirlwind tour of the greenest, grooviest building materials hitting the scene. From mushroom-bearing columns to bricks made from construction waste, the question isn’t just “How green can building materials get?” but also “What will they think of next?” With innovation like this, the sky’s the limit.

About Resource Erectors

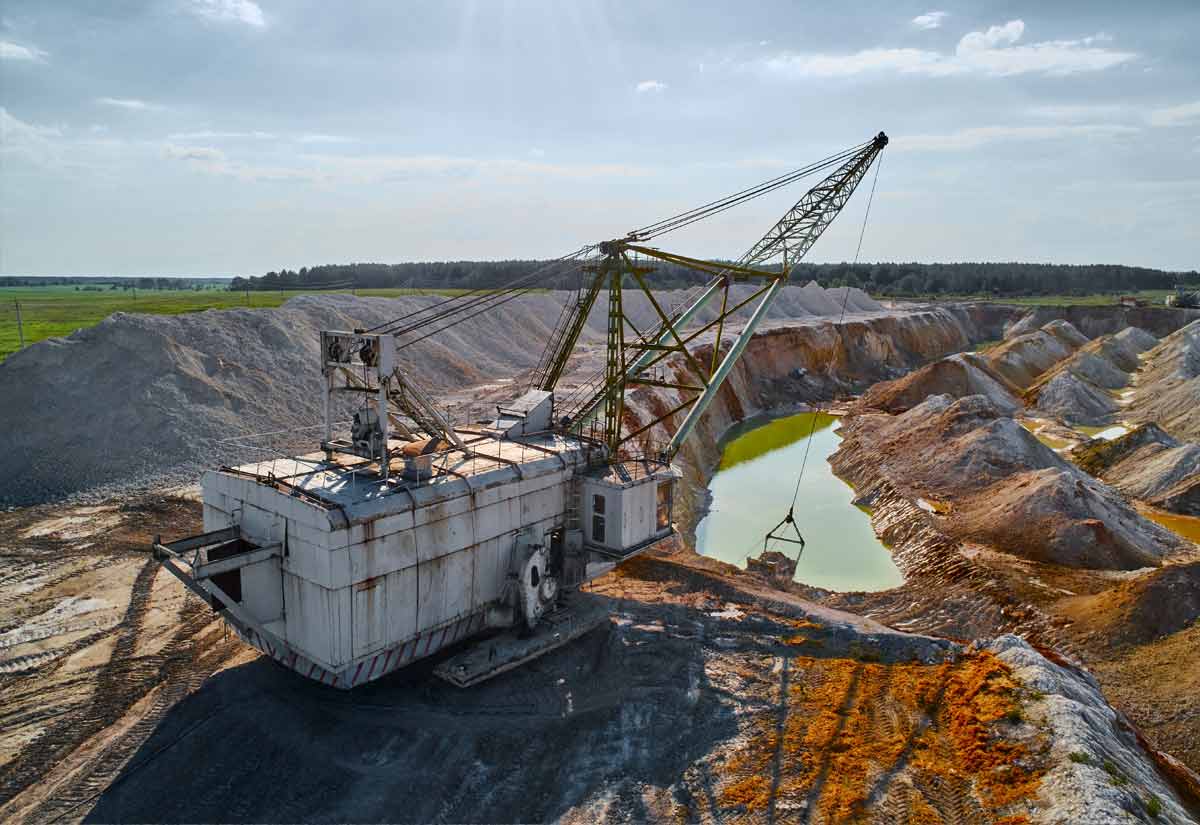

Resource Erectors connects highly qualified, top-tier professionals with leading companies in the heavy industry and engineering sectors, helping to foster the next wave of innovation in sustainable construction. With our keen eye on the evolving landscape of green building materials and advancing heavy industry technologies, our mission is to empower organizations by providing them with the talent they seek in today’s competitive economic environment.

When you’re ready to advance your professional career we have lucrative opportunities available all across North America, many offering substantial 6-figure salaries and competitive benefits for the right qualified candidates.

For heavy industry employers, we maintain ongoing connections with the experienced professionals you require to build your heavy industry dream teams in 2024. We bring decades of specialized HR experience to the table, recruiting professional candidates in industry sectors including, concrete, aggregates, mining, civil construction, bulk materials, engineering, sales, safety, and more, so don’t hesitate to contact us today so we can all get to work.