(Inspired by Mineralocity’s “Digging Deep: Tactics for Enhancing Your Current Aggregate Production”)

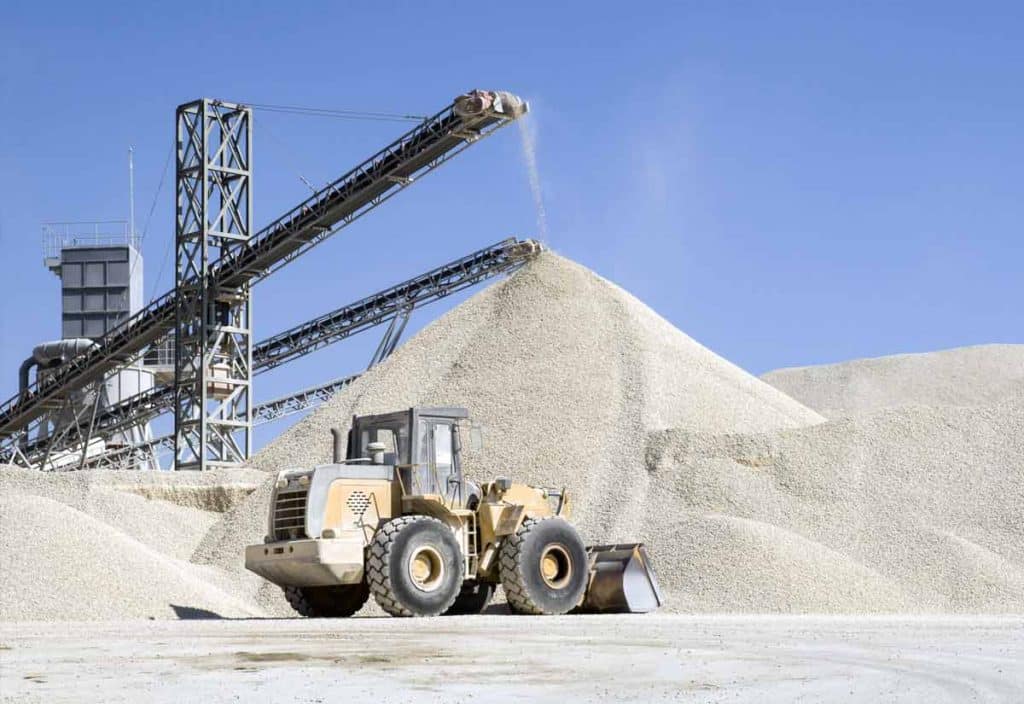

The aggregate industry forms the bedrock of construction, and optimizing production is crucial for success.

While exploring new production sites is always an option, unlocking the full potential of your existing operations can be a goldmine. Let’s delve into some key strategies to enhance your current aggregate production and ensure long-term sustainability.

1. Equipment Optimization: The Heart of the Operation

- Maintenance is Key: Regular upkeep and preventative measures prevent downtime and ensure your equipment operates at peak performance.

- Maximize Runtime: Optimize shift schedules and minimize downtime to get the most out of your machinery. Real-time monitoring tools can identify potential issues before they escalate.

- Right-Sizing Equipment: Match equipment capabilities to the specific needs of your operation. Using oversized equipment leads to unnecessary costs, while undersized equipment hinders production goals.

“We’ll make it fit George.”

- Investing in Your Operators: Training programs ensure efficient and safe equipment operation, reducing errors and maximizing output.

- Upgrade Wisely: Embrace technological advancements by evaluating and upgrading to more efficient or automated machinery when it makes sense for your operation.

- Custom Solutions: Consider modifications or custom-built equipment to address your site’s unique challenges and optimize production.

2. Streamlining Operations: Efficiency is Everything

- Continuous Improvement: Implement ongoing training programs to enhance operator skills and overall efficiency, reducing waste and boosting productivity.

- Workflow Optimization: Identify and eliminate bottlenecks in your production process to create a seamless and efficient workflow.

3. Resource Management: Working Smarter, Not Harder

- Extraction Evaluation: Explore alternative extraction methods based on your site’s geological characteristics to minimize waste and maximize material recovery.

- Embrace Recycling: Invest in equipment that allows you to recycle used aggregates, reducing waste and opening new revenue streams. Such as getting a government grant courtesy of the EPA.

4. Quality Control: The Cornerstone of Customer Satisfaction

- Advanced Testing: Implement advanced testing procedures to guarantee your aggregates meet industry standards, ensuring customer satisfaction and minimizing product returns.

- Feedback Loop: Establish a system for gathering and implementing feedback from end-users to continuously improve product quality and meet market demands.

5. Planning for the Future: Mapping Your Success

- Exploration and Assessment: Utilize techniques like exploratory drilling to identify untapped reserves of high-quality aggregates within your existing site.

- Mine Planning: Update or create a comprehensive mine plan to guide your operations, ensuring efficient resource extraction and sustainable practices. Collaborate with geologists and mining engineers to leverage their expertise.

6. Expert Insights: Fresh Perspectives, Innovative Solutions

- Consultants: Engage external mining consultants to gain fresh insights and identify areas for improvement.

7. Technology: Embrace the Future

- Automation: Implement automated systems for production, loading, and transport to enhance efficiency and reduce labor-intensive tasks.

- Real-Time Monitoring: Utilize IoT sensors, 5G technology, and equipment to gather real-time data on equipment health, production rates, and operational efficiency.

- Data Analytics: Leverage data analytics to identify patterns, predict maintenance needs, and optimize production processes.

- Drones: Employ drones for site mapping, stockpile measurements, and monitoring for faster and more accurate data collection.

- Software Solutions: Invest in industry-specific software for tasks like inventory management, production tracking, and predictive maintenance.

- Sustainable Technologies: Explore eco-friendly technologies that reduce emissions, conserve water, and minimize waste.

- Mobile Apps: Equip your team with mobile applications for enhanced communication, reporting, and monitoring capabilities.

By implementing these strategies and embracing continuous improvement, you can ensure your aggregate operations reach their full potential. Remember, optimizing your existing resources is the smart and sustainable path to success in the ever-evolving aggregate industry.

Optimizing Human Resources With Resource Erectors

With decades of specialized heavy industry recruiting experience and connections to the top companies and professionals all across North America, optimizing your workforce in today’s dynamic employment arena is a mission accomplished with Resource Erectors.

And no that’s not a typo, one to five years can get you on the fast track. If you’re moving up the career ladder in aggregates, concrete, sand, minerals, mining, plant management, project management, process engineering, bulk materials, civil engineering, and heavy construction make sure to check out our job board to take that next step in your heavy industry career. And don’t hesitate to contact us today so we can all get to work.