“Phosphate in North America is depleting. In terms of purified phosphoric acid (PPA), you cannot create any more of it. It’s already being used for food. There’s not a lot of extra capacity for the battery, but batteries are going to require a lot more PPA,”- First Phosphate CEO John Passalacqua.

There Ain’t No Such Thing As A Free Lunch! That’s the TANSTAAFL rule coined by celebrated author Robert Heinlein in the mid-20th Century, and one that still applies to engineering and mining even more than ever in the ubiquitous 21st Century green transition.

While lithium ion technology , as we’ve reported over the years, has long been touted as the green savior in an all-electric greentopia, there’s always a tab to pay. Cobalt is the current demonized mineral, but it turns out that phosphate may just be a bit too popular to come cheap.

A brave new green “all-electric” energy grid is the vision promoted by Big Tech moguls such as Elon Musk and Jeff Bezos; a fossil-free pipeless dream backed by non-engineer, self-appointed green politico elites such as less than lovable Klaus Schwab and the bottom-of-the-barrel think tank of the WEF. Ironically, whenever the Weird Elite Forum calls a meeting to decide how you will own nothing and be happy in their all-electric collective, flocks of private jets leave carbon footprints in the skies over Switzerland that would make Big Foot jealous.

Of the 6 major types of lithium-ion batteries, LFPs have been gathering momentum for use in short-range EVs and energy storage applications. While the standard green corporate line states unsurpassed safety and longer life cycles as the reason for LFP popularity these days, it’s also pertinent that lithium iron phosphate batteries are cobalt free. But unlike hard-to-mine and hazardous-to-process cobalt, phosphates in PPA (purified phosphoric acid) form are already in high demand.

In fact, you might be eating some for lunch. But in competition with the demand for LFP mass manufacturing, it will be anything but free.

What’s For Lunch? The Purified Phosphoric Acid (PPA) Market

The battery sector already claims 10% of all PPA production and that’s the number before the LFP craze kicked into high gear. The other 90% is distributed among markets including:

- The food industry

- Animal feed

- Big Pharma

- Fire Safety

- Electronics

You’ve already consumed some PPA yourself if you’ve had soft drinks, milk, cottage cheese, buttermilk, or other processed foods such as cereal bars, flavored waters, bottled coffee beverages, and processed meats.

This high demand in an assortment of economic sectors is even more concerning when we look at total US PPA production which has declined steadily from 14,000 metric tons in 1990 to a paltry 6,300 metric tons in 2019, according to the graphic nosedive on the chart at mining.com.

Now, with politically correct LFPs seen as the solution to the cobalt problem, the mining industry will once again be expected to provide an adequate supply for every green demand. But reversing the PPA production nosedive is already a work in progress for one North American company.

First Phosphate is First in Line to Meet Booming PPA Demand

“First Phosphate Corp is a mineral development company fully dedicated to extracting and purifying phosphate for the production of cathode active material for the Lithium Iron Phosphate battery industry. The company is committed to producing at high purity level, at full ESG standard and with [a] low anticipated carbon footprint.”- First Phosphate Corporate Update

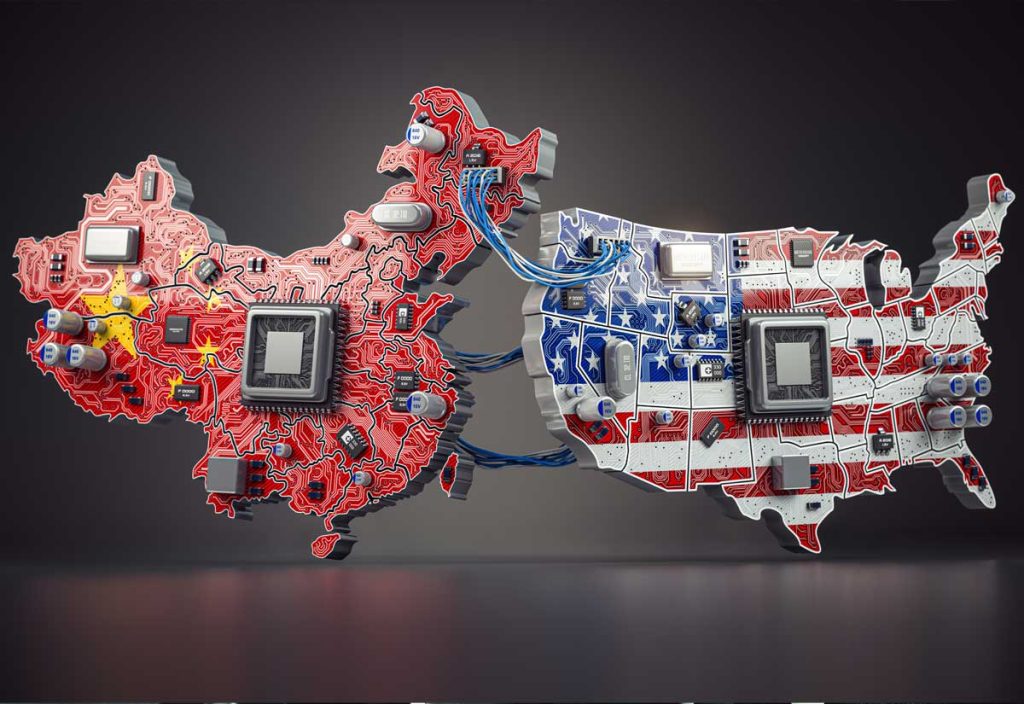

Currently China, as usual, dominates the LFP manufacturing sector with over 90% of lithium iron phosphate batteries currently made in China. The present LFP battery market share of 30% of all lithium-ion battery production is expected to expand from $10 billion in 2021 to $50 billion by 2028.

That is, if PPA production can be accelerated to avoid phosphate shortages beginning as soon as 2026 and becoming severe by 2028.

First Phosphate’s mining assets cover an entire district of 1,500 square kilometers in the Saguenay-Lac-St-Jean Region of Quebec. That’s the prime location where the top 1% of the world’s rarest and purest igneous anorthosite phosphate rock lies waiting. The company holds at least “15 areas of very strong phosphate showings that range from exploration sites all the way to PPA development assets”.

First Phosphate is relying on their partner company and the phosphorus chemistry specialists at Prayon to achieve an ambitious goal. The target is an impressive 90% of phosphate concentrate production being processed into ESG-compliant PPA for the production of LFP Cam (cathode active material) for LFP batteries.

First Phosphate sees a “core competitive advantage” over other sedimentary phosphate mines in North America that have continuously depleted phosphate stocks and can convert only a much lower percentage of their phosphate rock into PPA at an economically feasible scale.

The company is counting on smaller, low CAPEX mining operations combined with low carbon footprints and exploitation of profitable secondary tailing minerals from their prime source. Investigations are underway into the creation of more LFP raw materials such as iron sulfate and iron powder from secondary recoveries of ilmenite and magnetite.

Enhancing output of secondary recoveries of ilmenite (titanium) and magnetite (iron) to boost the economic potential of the Lac-à-l’Orignal mineral resource from mining 90,000 tons of LFP cathode active material production by 2032 is a pillar of First Phosphate’s strategy for their prime mining real estate in Quebec.

The ultimate downstream clients for First Phosphate production will be the LFP battery cell and battery pack producers as well as the OEM manufacturers of electric vehicles, small and large energy storage units, and other electrical devices.

About Resource Erectors

At Resource Erectors, we know there’s no such thing as a free lunch when it comes to recruiting and retaining the top professional talent in mining, engineering, sales, safety, civil construction, concrete, aggregates, and more. That’s why our industry-leading company clients rely on Resource Erectors to offer some of the most competitive benefits and compensation packages with lucrative career opportunities all across North America. When you’re ready to enhance your company or heavy industry career you’re ready for Resource Erectors so don’t hesitate to contact us today so we can all get to work.