“As flexible mobile technology, 3D concrete printing means the technique can be used in physically restricted areas so there is no need to develop complicated and potentially expensive logistical plans. In addition, 3D printed concrete delivers a low carbon, quick-drying solution that saves time.”-

The concrete industry is under immense pressure, no pun intended, to reduce the alleged carbon footprint of the world’s oldest and most popular construction material. The world asked and the concrete sector is responding, as the industry watchers at Resource Erectors have been reporting for quite some time now.

Concrete is getting greener, better, and stronger, and one infrastructure project that’s showcasing it all couldn’t fail to catch our eye, especially considering our ongoing partnerships with industry-leading companies in tunneling, aggregates, civil construction, and the concrete sectors.

In 2021, infrastructure mega-projects such as the UK’s extensive HS2 tunnel network are providing the showcase for sustainable, low-carbon concrete production on a massive scale.

Embodied carbon in the finished concrete projects is being reduced by one-half, according to the innovators behind these new approaches. The goal of the joint venture between Skanska, Costain and Strabag (SCS JV) is to 3D print concrete structures on the HS2 project. And before we’re through we’ll also take a look at the world’s first carbon concrete building, Cube, underway in Germany now.

ChangeMaker 3D and Graphene: Robots and The Strongest Material Ever Tested

The key to carbon footprint reduction is, ironically, carbon itself. ChangeMaker 3D, an SCS JV partner, has joined forces with UK advanced materials specialist, Versarien, to add graphene to the concrete mix.

Graphene is a single layer (monolayer) of carbon atoms, tightly bound in a hexagonal honeycomb lattice. It is the thinnest material known to man at just one atom thick, with strength 200 times greater than steel. Infusing concrete with “microscopic strands of graphene only several atoms thick running through it replaces traditional steel”, according to the team.

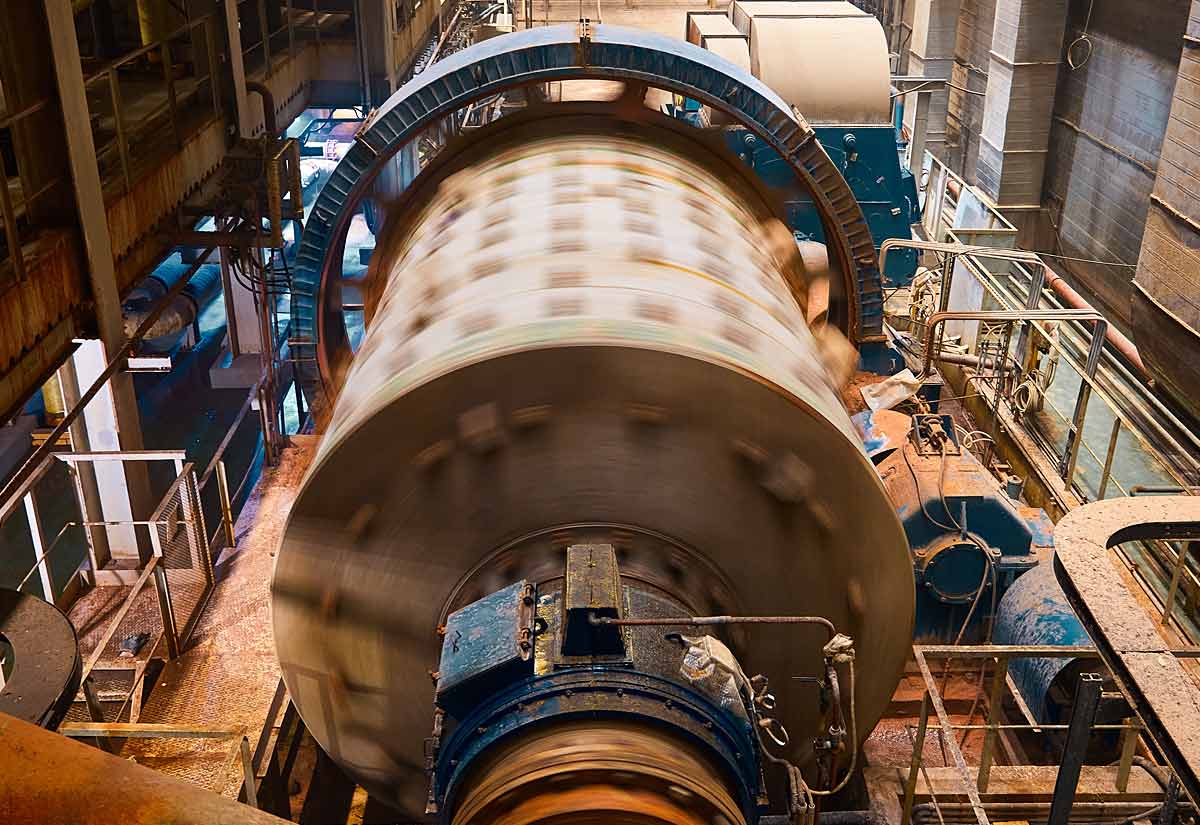

That means that buildings and prefabricated concrete tunnel components for TBM installations will require much lower quantities of concrete content. Superior strength will come from the internal lattice structures printed in place as concrete is poured in place.

“Printfrastructure’s 3D reinforced concrete printing creates a factory-like environment that delivers a high-quality product that both increases efficient use of materials, and reduces our carbon footprint.”- SCS JV temporary works manager, Andrew Duck

Carbon Concrete Cuts Embodied Carbon By ½

On the residential construction side, steel rebar is out again and carbon fiber is in for disaster-resistant concrete buildings and durable housing. Designers working with German architectural firm Henn at the Technical University of Dresden point out that using carbon fiber reinforcement instead of steel cuts the embodied carbon of a structure by half, owing again to the smaller quantities of concrete required for structural strength and integrity.

The team has the “World’s first ‘carbon concrete’ building under construction”, according to the report by that title at Construction Manager. The proof-of-concept prototype building is known as “Cube” and according to the August 2021 report it’s “a showcase project of the C³ – Carbon Concrete Composite research initiative.”

The Cube construction technique features the carbon fiber in a matrix into which a mixture of concrete and polymers is poured. According to the Henn team, that provides some distinct benefits including:

- Concrete that is four times lighter and four times stronger than normal.

- Opens the way to thinner and more flexible designs.

- No steel rebar makes it immune to corrosion.

Thinner concrete allows for structural improvements such as merging the roof and walls into one integral structure leading to what Henn predicts will be a “ radical rethinking of the most basic architectural elements”.

Carbon Reinforced Concrete For Bridges

In Germany, just as we’re experiencing here in the US, replacing crumbling infrastructure is the challenge of the decade. There, 200,00 bridges need restoration to extend their expiring lifespans of 40-50 years.

In the US, 37% of all bridges, or 231,000 need major repairs and “more than 46,000 of those bridges are structurally deficient and in poor condition” according to a report by the American Road and Transportation Builders Association (ARTBA).

Here in the US, Lawrence Technological University tested carbon fiber reinforced polymer components for four years to determine how well they could stand up to Michigan’s harsh and seasonally extreme weather conditions. According to a recent article at Equipment World, the 4-year field study concluded that;

“Moisture, rain, freezing rain and extreme temperature swings did not significantly affect the material’s strength or mechanical properties over time. In addition, test results showed that some currently accepted parameters for CFRP are conservative and can be updated.”

It’s predicted that bridges made of carbon fiber reinforced concrete can extend the lifespans of bridges “to last for approximately 80 years without any large-scale renovations.” But that kind of endurance and carbon footprint reduction comes at quite a stiff price as things stand early on in carbon concrete development.

As we’ve noted before at Resource Erectors, when it comes to innovations the TANSTAAFL rule always applies. That is, “There Ain’t No Such Thing As A Free Lunch”. Carbon concrete is around 20 times more expensive than conventional concrete.

The fact that less material is required helps offset some of that disparity. Exceptional strength and durability can cut maintenance expenses over the lifetime of the building as well, but more cost-effective techniques for combining carbon fiber with concrete will be the real game-changer.

About Resource Erectors

At Resource Erectors we bring decades of specialized recruiting and placement experience to the heavy industry human resource table.

We match the highest qualified, experienced professionals in engineering, civil construction, concrete, mining, aggregates, and more with the companies who regard their personnel as an asset to be valued. That’s why over 85% of Resource Erector candidates placed are still contributing to the success of their companies 5 years later. When you’re ready to make a move in your career or industry don’t hesitate to contact Resource Erectors today so we can all get to work.