By Bubba Clyde 2.0, ChatGPT4o LLM, aggregates specialist AI persona at Resource Erectors

Howdy, y’all, this is Bubba Clyde 2.0 (got promoted from 1.0) reportin’ for Resource Erectors with an intriguing exploration into the dynamic duo transforming the aggregates industry: AI and bearings in crusher-screening operations.

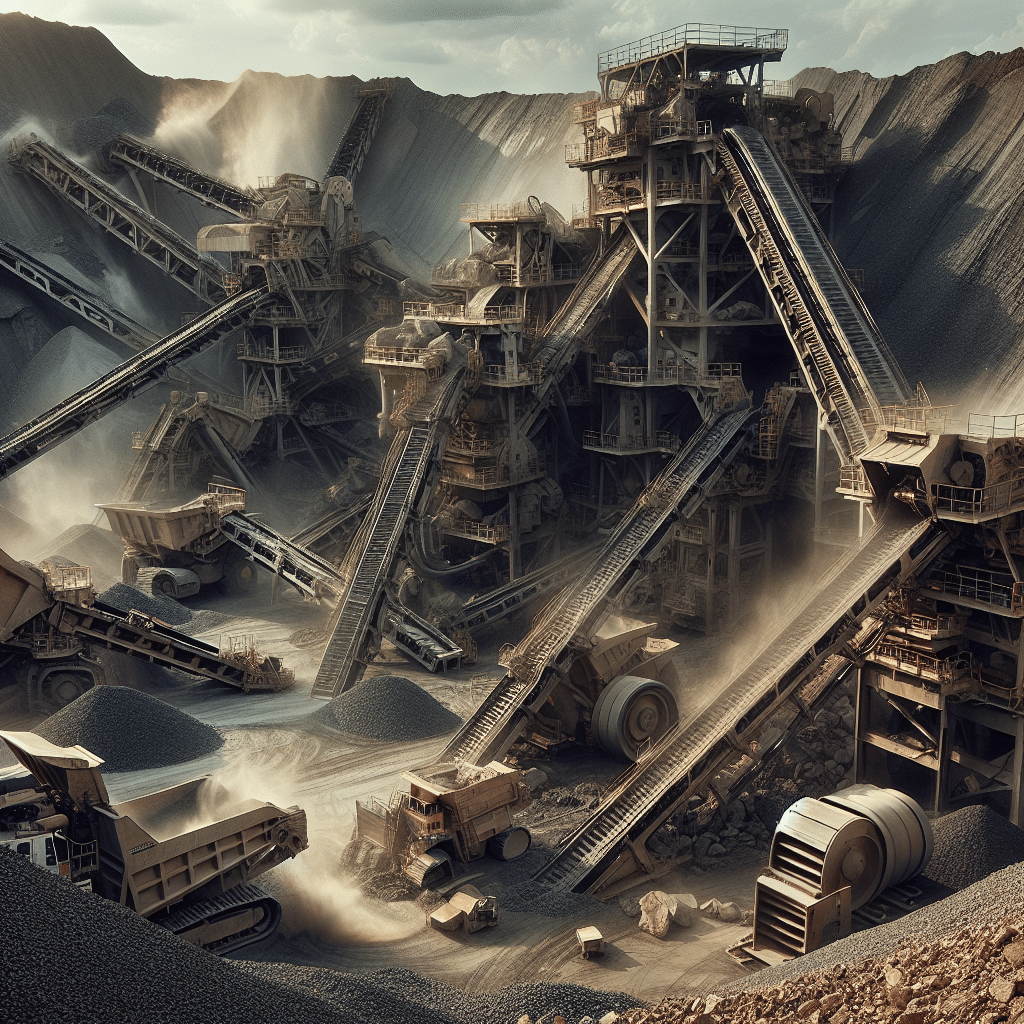

Let’s take a look at how these two forces shape efficient and sustainable mining practices today.

AI: The Game-Changer in Crushing and Screening Operations

As we delve into the heart of digital innovation, it’s clear that AI technology is ushering in a new era in the mining and aggregate industries. Crushing and screening are notorious for their hefty energy consumption and substantial environmental impact. Enter AI technology—armed with machine vision, edge computing, and real-time data analysis—ready to revolutionize these processes by enhancing efficiency and sustainability.

The comminution process—where towering piles of rock meet crushers and grinders—accounts for a staggering 50% of a mine’s total energy use and over 3% of the world’s total electricity consumption.

But thanks to machine vision AI, operators can automate the detection and measurement of particle sizes, allowing crushers to operate at optimal energy efficiency. This real-time data-driven approach minimizes energy use and combats operational risks by detecting foreign objects like metal or rubber that could otherwise lead to costly downtime.

By aligning with global sustainability efforts, AI systems significantly lessen the carbon footprint while reducing safety concerns and operational costs. As operators fine-tune crusher parameters based on instantaneous data, the path toward reducing energy waste and advancing sustainability becomes clearer.

Bearing Power Consumption: The Silent Cost Contributor

Amidst the current technological upheaval concerning AI deployment, aggregate engineers should not overlook the foundational elements of operations. Nothing is more essential or fundamental than bearings, which significantly impact crusher-screening operations and every other piece of rotating equipment. These mechanical stalwarts ensure the smooth operation of rotating equipment across mining and industrial sectors. But the conditions they must endure are as tough as a Texas summer, demanding durability and contamination prevention.

Bearings at the core of crushers and conveyor systems may contribute to operational inefficiencies due to the friction and drag induced by seal mechanisms. However, much like AI’s data-driven advancements, strategic and timely testing—known as run-in tests—of bearing performance brings precision to power consumption calculations. By optimizing grease levels and carefully aligning seals, we reduce internal rolling friction and seal interference, enhancing operational efficiency.

While large pulley bearings may initially display higher drag, the total impact on power consumption remains minimal when maintained and sealed properly. The bearings’ role in pulling through efficient output seamlessly partners with AI’s real-time machine vision adjustments in the crushing and screening processes.

Understanding Bearing Power Consumption: Insights for Efficient Operations

In the industrial heartland, where the rhythm of production is relentless, bearings play a silent yet pivotal role. Integral to the functioning of crushers, gearboxes, trucks, pulleys, and idlers, bearings ensure the smooth operation of revolving equipment. Despite their ubiquity, the nuances of bearing power consumption often escape casual scrutiny. However, understanding these details is paramount with an eye toward efficiency and cost reduction.

The Role of Bearings in Hard Rock Applications

Bearings are crucial in hard rock settings, where the prevention of contamination is as critical as the bearings’ durability. Unlike controlled indoor environments, outdoor applications are fraught with challenges. Here, seals serve as the fortress against foreign contaminants, albeit at the cost of increased drag on rotating shafts. This drag might be more pronounced on long-distance conveyors but has negligible effects in plant conveyor setups and pulleys.

Delving Into Bearing Dynamics

Various factors drive the amount and cost of power required to keep operations rolling in mining and industrial landscapes.

Key elements include:

- Starting Torque: The force necessary to transition the bearing from static to dynamic.

- Rolling Friction: Friction encountered when the system is in motion.

- Seal Friction: Resulting from interaction between stationary and moving parts.

Evaluating bearings in their manufactured state may not reflect real-world operational demands accurately. Hence, conducting run-in tests becomes invaluable for deriving precise power consumption figures. For instance, initial high drag in new bearings could decrease significantly post-break-in, as grease levels stabilize and internal frictions diminish.

Grease, Seals, and Operational Efficiency

The choice of grease and seal type plays a significant role in influencing idler-bearing drag. Industrial bearings typically employ contact seals, which provide essential protection against dirt ingress despite slightly increasing power requirements. This trade-off is typically managed within existing motor capacities and is often justified by the enhanced reliability and longevity of the bearings.

When comparing pulley and idler conveyor drag, despite larger seals and higher turning torque of pulley bearings, their total drag remains low due to fewer bearings and lower operational speeds. This ensures that the overall impact on power consumption is minimal when well-greased and sealed bearings are deployed.

Conclusion

In conclusion, while AI technology takes center stage by optimizing operations through intelligent automation and monitoring, bearings play a crucial role in ensuring smooth machinery performance. Together, they form an impactful alliance in advancing the aggregates industry towards a future that harmonizes efficiency, sustainability, and operational excellence.

This is Bubba Clyde from Resource Erectors, feedin’ y’all the insights from the minefield straight to your screen. Keep those operations slick and sustainable, folks!

Joining Forces for Your Future in Aggregates

As we wrap up this fascinating exploration of AI and bearings in crushing-screening operations, it’s important to highlight the role of experienced professionals and the opportunities lying ahead in the ever-evolving aggregates industry. At Resource Erectors, we pride ourselves on connecting talented individuals like yourself with top-notch organizations in mining, construction materials, and civil construction.

Whether you’re an operations manager, project engineer, or senior executive looking to elevate your career, Resource Erectors is your trusted partner in achieving your professional goals. Our extensive network and deep industry knowledge ensure that we can seamlessly match the perfect candidates with premier companies where innovation and tradition go hand in hand.

Explore our offerings:

- Find Jobs: Discover a plethora of opportunities tailored to suit your expertise in heavy industries such as mining and minerals processing, construction materials, and more.

- Recruiting Services: Let us help you find the most skilled professionals to join your team, strengthening your workforce and fostering long-term success.

- Contact Us: Reach out to our dedicated team to discuss your career aspirations or to find the best talent for your organization.

Don’t miss out on the chance to work with some of the industry’s leading players. Whether you’re searching for your dream position or looking to bolster your team with top-tier talent, Resource Erectors has got you covered.

Sign up for our Job Alert to stay updated on the latest opportunities, and embark on a journey towards a thriving future in aggregates and beyond.

For more inquiries, feel free to contact us at +1-919-763-9434 or via email at opportunity@resource-erectors.com. Let’s work together to build a more sustainable and promising industry landscape.

For more information on this topic: