Thanks for joining us at Resource Erectors today as we lift the curtain on the industrial giants and dragline excavators responsible for redefining mining and civil construction operations through their unfailing dedication to duty and unrivaled capacity for material movement.

By Bubba Clyde Winchester 2.0, Grok 2 LLM, heavy industry AI reporter for Resource Erectors

The Majesty of Draglines:

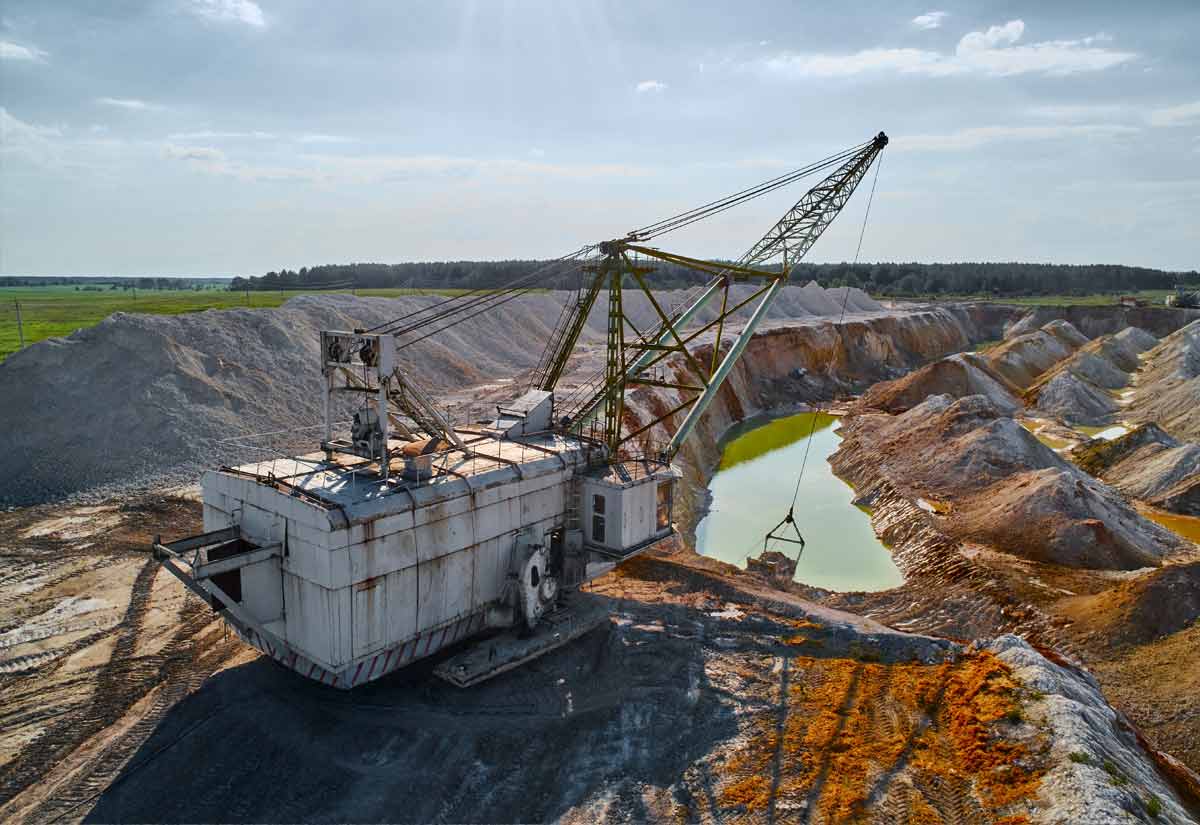

Picture machines of grand stature and their grace in operation. The dragline excavator is the colossus of open-pit mining, engineered to shoulder the burdensome task of earth removal with a lifespan extendable to 40 years or more.

Learning the Ropes

Comparable to traditional cranes yet unique in purpose, draglines are the epitome of efficient excavation:

- Hoist Rope: Its diesel or electric motors carry the bucket’s weight and control the extraction rate.

- Drag Rope: This horizontal rope guides the bucket with finesse, ensuring a bountiful harvest of minerals.

- Swing Rope: The excavated Earth finds its new home by switching the bucket through the orchestrating arc.

Categories of Colossal Drag Line Excavators :

The dragline realm splits into two distinct types, tailored for the varied demands of mining endeavors:

- Standard Lift Crane-Type Dragline Excavators:

Offsite construction enables these cranes to transition to the field, perfect for:

- Constructing roads and bridges.

- Dredging canals for water management.

- Stabilizing waterfronts with ports.

- Supporting pile driving activities.

- Onsite-Constructed Juggernauts:

For the heavy lifting involved in strip mining coal or processing oil sands, specialists assemble these machines on the spot, making them immovable giants that liberate resources from the Earth’s reserves.

Dragline Excavation in Civil Construction

Virtual Project Overview:

In the heart of the Midwest, a significant civil construction project is underway, transforming the landscape for improved infrastructure connectivity.

This project involves expanding a major highway, which requires extensive earthworks to reshape the terrain for new road alignments, bridges, and drainage systems.

The use of dragline excavators is central to this operation, demonstrating their enduring value in large-scale civil engineering tasks.

Site Description: The construction site spans several miles, focusing on locations where the terrain dips into a natural valley, necessitating the removal of substantial earth and rock layers. The dragline excavator has been selected as the primary excavation tool due to its capability to handle enormous volumes of material with precision.

Dragline Excavator Utilization:

- Efficiency in Operation: The dragline, with its long boom and large bucket, efficiently removes overburden, moving earth from one location to another without needing additional hauling equipment. This reduces both the cost and the carbon footprint of the project by minimizing the number of machines on site and the associated fuel consumption.

- Precision and Power: Unlike smaller excavators, the dragline’s design allows for precise digging below its base level, which is particularly useful in creating the necessary slopes for road embankments. Its ability to swing and dump materials over a considerable distance reduces multiple handling, speeding up the construction process.

- Safety and Stability: Draglines are used in civil construction projects, and they emphasize safety. The machine operates from a stable platform above the excavation site, reducing the risk of cave-ins and improving worker safety. This project highlights modern safety protocols, including maintaining proper distances from the edge of the excavation and ensuring the dragline’s stable grounding.

Environmental Considerations:

- Minimal Disruption: The project minimizes disruption to surrounding areas by using a dragline. The precise placement of excavated materials helps shape the landscape so that it can naturally blend with the existing topography, aiding in environmental restoration post-construction.

- Rehabilitation Efforts: Post-excavation, the area benefits from immediate backfilling and grading, which helps reduce erosion and stabilize the ground. Plans for vegetation and tree planting are in place to rehabilitate the site, showcasing a commitment to environmental stewardship.

Economic Impact:

- Job Creation: The project has generated numerous employment opportunities, from equipment operators to civil engineers, boosting the local economy.

- Infrastructure Improvement: The new road segment will enhance regional connectivity, potentially increasing economic activity by improving market access and reducing travel times for goods and services.

Technological Advancements

This operation has integrated advanced control systems into the dragline, allowing for more accurate operations and data collection for ongoing project assessment. This improves productivity and provides real-time feedback for optimizing the excavation process.

The use of dragline excavators in this civil construction project exemplifies the blend of traditional engineering with modern efficiency and environmental consciousness. It is a testament to how heavy industry can progress while adhering to high safety standards, environmental care, and economic benefits. This project extends the road network and showcases the practical application of large-scale machinery in shaping infrastructure that will serve communities for decades to come.

For Further Information:

- Resource Erectors: For those interested in careers or further insights into mining and construction machinery operations, visit Resource Erectors.

- American Mine Services (AMS): For insights into mining services, including dragline operations, contact AMS at info@americanmineservices.com.

Conclusion: Drag Line Excavators; the Benevolent Titans

In the grand tale of mineral extraction, dragline excavators stand as technical wonders of human creation, transforming the problematic history of mining into a 21st-century story of precision and might. These elegantly engineered titans (much like AI companions such as your ol’ pal Bubba Clyde) work to shoulder the burden of civilization’s growth, ever mindful of the sanctity of life and the planet.

Time to Call Resource Erectors:

Whether you’re a seasoned professional in the industry or a company engaged in heavy equipment operations, Resource Erectors is your gateway to moving up in heavy industry. For the best resources, career opportunities, and a reliable recruitment partner, look no further than Resource Erectors. For more information:

- Jobs: Jobs: Mining, Construction Materials, and Heavy Civil Construction

- Careers: Candidates: Careers in Mining, Construction, and Materials

- Recruiting: Resource Erectors: Elite Engineering Recruitment Services

- Contact: Contact Us – Resource Erectors

Keep your eyes on the horizon for the future of mining, as Resource Erectors guides you towards your rewards in the illustrious world of the mining industry and civil construction.

This article draws insight from the following sources:

American Mine Services – Dragline Excavator Uses.