In a Resource Erectors blog last May we featured the showdown between lithium lothario Elon Musk and Australia’s mining and energy icon, billionaire Andrew Forrest. In that case the billionaire standoff centered on hydrogen “blue gas” as a much more plentiful fuel for powering the proposed all-electric fleets for the world’s biggest EV customer, which happens to be China.

“Even in CW’s (Composite World) Oct 2020 feature, Carbon fiber in pressure vessels for hydrogen, there was still serious doubt as to whether the long-awaited H2 economy would actually materialize.” – Ginger Gardiner- Composites World

Now a few months later it looks as if the long-anticipated, somewhat doubtful hydrogen economy seems to be a rapidly expanding reality. But large-scale hydrogen storage brings with it a host of engineering choices and challenges.

Large-scale storage and infrastructure for distribution for the zero-emissions hydrogen fuel is already in demand as letters of intent between forward-thinking corporations are signed.

In her article at Composites World, Senior Editor Ginger Gardiner noted that the hydrogen economy is already shifting into higher gear with exciting news including:

- Universal Hydrogen in Los Angeles has taken on the ambitious mission of “Fueling carbon-free flight”. The California company recently signed letters of intent with three regional airlines to retrofit existing turboprop aircraft with H2-powered propulsion systems.

- Cimmaron Composites in Huntsville, Alabama was acquired by Hanwha Solutions in Seoul, South Korea. They’re now known as Hanwha Cimmaron and the H2 storage tank manufacturer is kicking off a new $130 million production facility in Opelika, Alabama.

- Composite tank manufacturer, NPROXX of Heerlen, Netherlands, entered into a 50/50 joint venture with Cummins in Columbus, Indiana, the revered manufacturer that produces 130 million internal combustion engines per year and which has now invested in a strategic pivot to H2-producing electrolyzers, H2 engines, fuel cells, and storage tanks.

Hydrogen Tanks and the Challenges For Engineers

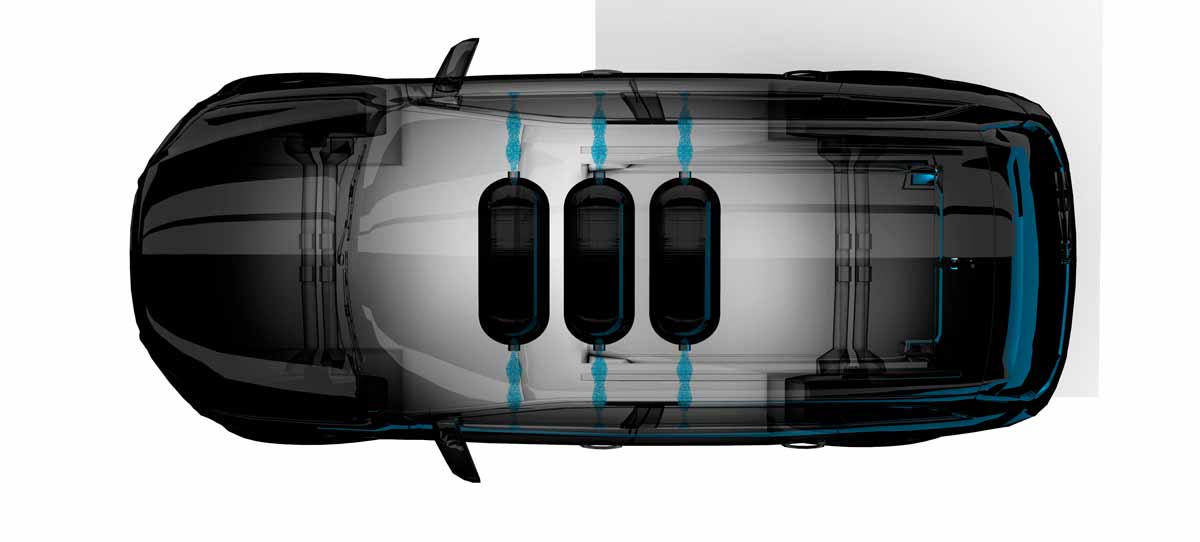

Carbon fiber composites are all the rage now in the hydrogen storage tank industry, and R&D is focused on developing the robust composites that can match or surpass the performance of Type IV metal tanks.

While hydrogen is indeed plentiful and compressed H2 gas offers three times the energy per mass of gasoline, its energy per volume is much lower. That means large, durable cylinders are required to withstand the high compression pressures and frigid temperatures needed to store enough fuel cost-effectively.

- Hydrogen offers higher density as a cryogenic liquid, when stored at -253°C.

- Highest density can deliver 50% more H2 versus 700 bar Type IV tanks when cryo-compressed (CCH2) tanks at -230°C and 300 bar are used”

- High cost of carbon fiber significantly increases TCO.

As it stands now, metal H2 tanks still have the edge. Composites have yet to equal or surpass the solid performance and fatigue life proven in Type IV compressed gas tanks. These storage stalwarts now have more than 25 years of performance data behind them.

One company is sticking with traditional metal. The company was founded by a top former BMW engineer, Dr. Tobias Brunner, to meet future demand. Cryomotive in Grasbrunn, Germany, got underway in 2020 and is busy developing metal CCH2 tanks based on Dr. Brunner’s engineering and R&D work for esteemed automotive giant BMW in Munich, Germany.

Hexagon Purus is another upstart company in the H2 sector. The new subsidiary is leveraging their time-tested H2 storage solutions for markets like distribution and the heavy truck sector. Their goal now is to adapt their tanks to a broad range of ship sizes and architectures.

The company was spun off by Hexagon Composites (Alesund, Norway), a leader in Type IV tank production, specifically to focus on H2 applications, battery electric storage, and associated systems. With an anticipated 630% increase in tank revenues generated by demand for electric vehicles from 2025-2030, the light weight that carbon fiber Type IV tanks offer has driven their use versus metal alternatives.

More big news in the emerging hydrogen economy is one that will affect any industry that involves freight logistics that at one point or another rely on trucks to get materials and products smoothly through the supply chain. In other words, every industry that produces a product.

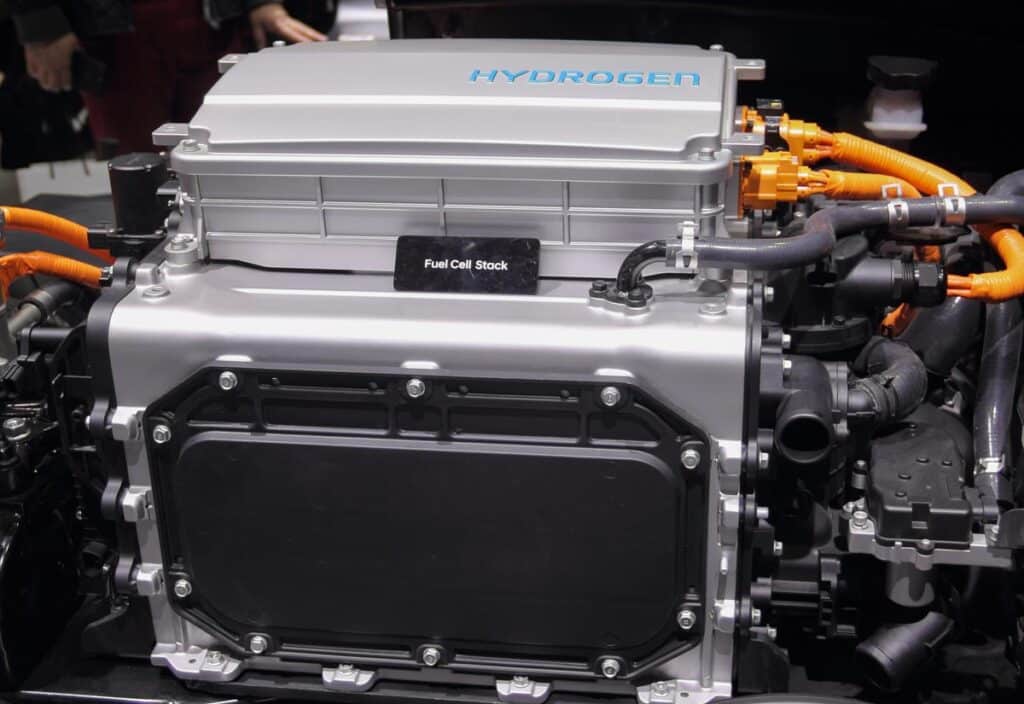

Class 8 Semi Hydrogen Fuel Cell Power and More Underway at Cummins

Cummins and long time truck builder Navistar have partnered since last November, 2020 with backing via a $7 million grant from the Department of Energy that:

“…will aid in the development of an integrated fuel cell electric powertrain for heavy-duty trucks with operational performance and total cost of ownership that supports near-term, rapid, and substantial penetration of the truck markets.”- Cummins Newsroom

The company is also developing hydrogen-fueled combustion engines with the eventual goal of replacing the almighty diesel engines and their reliance on fossil fuels. Looking ahead, Cummins vice president for New Power Engineering, Jonathan Wood, said that by the end of this decade, hydrogen-powered trucks will approach the total cost of ownership (TCO) of a compatible diesel engine. VP Wood predicts that the future of heavy-duty transport will rely on hydrogen, whether fuel-celled or combustion, completely phasing out diesel power.

It’s not just cost-effectiveness and profit that’s motivating H2 innovation at Cummins, the company that produces 130 million internal combustion engines per year. Investments in H2-producing electrolyzers, H2 engines, fuel cells and storage tanks are all part of meeting the ambitious 2030 sustainability benchmarks, that in places like Europe are mandated.

Michael Himmen, managing director and head of sales for H2 storage tank manufacturer NPROXX explained about this decade’s countdown to 2030 and the global pressure to move to sustainable energy with zero emissions:

“In Europe, we have legislation that mandates truck OEMs, by 2030, must achieve a 30% reduction in CO2 for their produced fleet, on average, compared with 2019 levels. So, some portion of truck production in Europe will be hydrogen powered, perhaps as much as 5%, which could be as much as 15,000-20,000 trucks/year.”

Cummins and Chevron Enter Strategic Hydrogen Collaboration

As the world’s manufacturers wake up to the hard fact that lithium, cobalt, and other essential battery metals are costly to locate, extract, and process, Cummins is moving full speed ahead to develop and build the hydrogen fuel infrastructure that exploits the universe’s most plentiful element.

Last July 2021 the company announced that it was collaborating with energy titan Chevron U.S.A. Inc., through its Chevron Products Company division to execute a strategic 4-point plan:

- Advance public policy that promotes hydrogen as a decarbonizing sustainable solution for transportation and industry.

- Build market share for commercial vehicles and industrial applications powered by hydrogen.

- Develop infrastructure to support the use of hydrogen for industry and fuel cell vehicles.

- Explore new opportunities to leverage Cummins electrolyzer and fuel cell technologies at one or more of Chevron’s domestic refineries.

When a traditional gas, oil, and lubricant giant like Chevron makes a strategic pivot to hydrogen and away from fossil fuel, can there be any doubt that the hydrogen economy is here and here to stay?

About Resource Erectors

At Resource Erectors we’ve made it our mission to recruit and place the top engineers and industry professionals for the leading companies seeking their talents in energy, mining, manufacturing, civil construction, aggregates, the concrete sector and more. We bring decades of specialized heavy industry recruiting experience to help your company avoid the high cost of vacancies in essential positions in your organization.

When it’s time to make a move up the career ladder we have the connections to match the top candidates with the top companies who know that their human resources are their most valuable resources, so please don’t hesitate to contact Resource Erectors today.