The landscape of heavy industry is undergoing a seismic shift towards sustainability, driven by climate change awareness and technological innovation. The year 2023 has proven to be pivotal for this transformation, as industries across the globe are actively embracing green practices. It’s no longer an optional pathway; it’s the future, and the future is now.

The transition to greener technologies is not just a trend restricted to the consumer sector. Sustainability and “carbon footprint” reduction have become significant focuses within heavy industry.

Whether it’s Mitsubishi Heavy Industries Engineering working on efficient CO₂ recovery or the Engine Technology Forum advocating for cleaner internal combustion engines, the paradigm shift to sustainable solutions is evident this year.

Let’s explore how heavy industry is playing its role in the green transition of 2023.

Engine Technology Forum: The Evolution of Diesel Technology Forum

Last week on October 2, 2023, the Diesel Technology Forum officially evolved into the Engine Technology Forum, signaling a transformative period and an expanded role in the green transition for internal combustion engines.

The organization aims to broaden its mission and sustainability vision to encompass not just diesel power, but also other types of internal combustion engines (ICE), like gasoline and natural gas. According to Allen Schaeffer, the Executive Director of ETF, internal combustion engines are, and will continue to be the bedrock of our global economy and mobility.

Expanding Scope at ETF

ETF now tackles a wide array of challenges and opportunities for ICEs, particularly in reducing greenhouse gas and other emissions. The forum works with various stakeholders, including government agencies, environmental organizations, and industrial sectors like freight transport, agriculture, construction, and mining.

More Inclusive Pathways to the Greener Future at ETF

Allen Schaeffer emphasizes that many pathways to a reduced carbon future exist. While some technologies are more certain and available today, others hold potential for the future. The forum promotes both advanced ICEs and zero-emissions technologies, providing holistic solutions.

ETF Corporate Member Base:

ETF boasts a broad member base, including heavy hitters like AGCO, Caterpillar, Cummins, General Motors, John Deere, and Stellantis. The diversity of its heavy industry members reflects the organization’s comprehensive approach to advancing ICE deployment and sustainable fuels.

BP’s (now bp) Green Initiatives

BP’s Peacock Solar project in Texas is a game-changer. Generating 187 megawatts of clean energy, the project aims to offset over 256,000 metric tons of greenhouse gas emissions annually. That’s akin to removing 55,000 cars from the road every year.

In a very significant move, bp has started construction on its 187MWdc Peacock Solar project, aiming to support the global transition to lower carbon energy. Located in San Patricio County, Texas, the project will supply power to Gulf Coast Growth Ventures, a joint venture partnering ExxonMobil and SABIC. The project will power the equivalent of 34,000 homes once completed and is expected to generate over $25 million in tax revenue over its 25-year lifespan.

And as we covered in our recent blog, “Environmental Trade-Offs in the Green Transition” bp is now leading the hydrogen fuel cell revolution with hydrogen refueling stations now open for hydrogen refueling business in Australia.

Stellantis & Samsung SDI: The New Power Couple

Stellantis N.V. and Samsung SDI are collaborating on their second battery manufacturing facility. With an annual production capacity of 34 GWh, this venture supports Stellantis’ goal to achieve “carbon neutral” by 2038.

As part of the Dare Forward 2030 strategic plan, Stellantis announced plans of reaching a 100% passenger car battery electric vehicle (BEV) sales mix in Europe and 50% passenger car and light-duty truck BEV sales mix in the United States by 2030. To achieve these sales targets, the company is securing approximately 400 GWh of battery capacity.

According to the Dare Forward 2030 website, A ” Bold Strategic Plan” is required, not only to embrace the green transition but to benefit stakeholders in the company as well.

“Powered by our purpose to lead the way the world moves, we are pushing the limits, expanding our vision, and embracing a new mindset. Everyone at Stellantis is focused on providing cutting-edge freedom of mobility for all.”- CEO Carlos Tavares

With their global diversity, a unique portfolio of iconic brands, and proven operational excellence, the Stellantis engineering team has crafted that bold strategic plan, one that paves the way for Stellantis to achieve carbon net zero by 2038. As the company works toward delivering on this ambitious but what they see as quite achievable objective, a benchmark for heavy industry, they are also intent on being ‘second to none’ in value creation for all stakeholders.

Presented in March 2022, Dare Forward 2030 is a plan that will lead Stellantis to achieve their financial ambition of doubling their Net Revenues by 2030 (with 2021 revenues as the benchmark) while sustaining double-digit Adjusted Operating Income margins throughout the decade.

Mitsubishi Heavy Industries: Pioneering a Sustainable Future

Mitsubishi Heavy Industries (MHI) is no stranger to the green energy transition. With decades of experience in engineering and heavy industry, MHI has become a global leader in CO₂ capture technologies. Their “KM CDR Process™” is a groundbreaking technology that can handle a diverse range of exhaust sources, making it incredibly versatile.

Advancements in CO₂ Capture

Starting in the early 1990s, MHI, in collaboration with Kansai Electric Power Company (KEPCO), developed a proprietary CO₂ capture system. This technology can recover over 90% of the CO₂ contained in the target gas and offers a purity rate of over 99.9%. MHI’s proprietary KS-1™ amine solvent for carbon dioxide removal has been implemented in 13 plants globally so far, asserting a commanding market share.

Moreover, their Advanced KM CDR Process™, utilizing KS-21™ solvent, takes the technology a step further. Compared to conventional solvents, KS-21™ offers superior regeneration efficiency, lower volatility, and greater stability against degradation.

Beyond CO₂ Capture

Mitsubishi isn’t stopping at CO₂ capture. They are conducting feasibility studies across various sectors, such as cement and steel plants. One unique project in their green portfolio is the world’s first CO₂ capture and storage initiative in an LNG liquefaction plant.

This is yet another holistic approach that makes MHI a key player in global decarbonization efforts. Their commitment to technology that minimizes operating costs while maximizing efficiency sets a strong precedent for heavy industries worldwide.

The Green Global Perspective and China’s Role

While heavy industry embraces the green transition in 2023 and beyond there is still a major challenge to be overcome. China, as a global manufacturing hub and a significant player in battery minerals, plays a vital role in the green transition. Its commitment to sustainable practices can have a global impact, but the government’s push to transition to hydrogen-powered vehicles is facing troubling resistance from Chinese consumers.

The massive population there provides a ready market for innovation in hydrogen fuel cell vehicles and EV adaptation on an enormous scale. But getting China’s consumers to forego lithium-dependent EV transportation in favor of hydrogen is proving to be quite an obstacle in recent years.

Stalled Progress: China’s Fuel Cell Vehicles Take a Back Seat to EVs

As electric vehicles (EVs) gain popularity with the expanding middle class in China, fuel cell vehicles find themselves at a crossroads. Beijing SinoHytec, China’s largest fuel cell manufacturer, is navigating a challenging market with tepid demand for its passenger cars, prompting a strategic shift toward commercial trucks and buses.

Sales for SynoHytec’s fuel cell vehicle, developed in collaboration with Changan Automobile, have been nearly nonexistent a year after its introduction, according to a 2023 report from Nikkei Asia.

High costs and inadequate hydrogen infrastructure are among the major hurdles. SinoHytec’s fuel cell vehicle, touted as China’s first mass-produced fuel cell sedan, carries a hefty price tag of 699,900 yuan. That’s a whopping $98,000 USD equivalent price that makes a Tesla EV seem affordable by comparison. Lack of hydrogen refueling stations has further dampened consumer interest. According to the China Association of Automobile Manufacturers, not a single fuel cell passenger car was sold in China for six consecutive months through May 2023.

The company is now pivoting to commercial vehicles, aiming to capitalize on the fuel cells’ advantages such as shorter charging times, longer cruising ranges, and better low-temperature performance.

Despite SinoHytec’s struggles, it remains the leading fuel cell supplier in China, accounting for 20% of the market. Government subsidies for fuel cell commercial vehicles are also keeping hopes alive. A 49-tonne fuel cell truck, for instance, can benefit from generous subsidies that bring the purchase price down to a more affordable 376,000 yuan (51,568.32 United States Dollars) compared to an EV truck costing 989,000 yuan.

China aims to have 50,000 fuel cell vehicles by 2025 to reduce annual CO2 emissions by 1-2 million tons. However, with only 3,681 fuel cell commercial vehicles sold in 2022, achieving this target remains a steep climb.

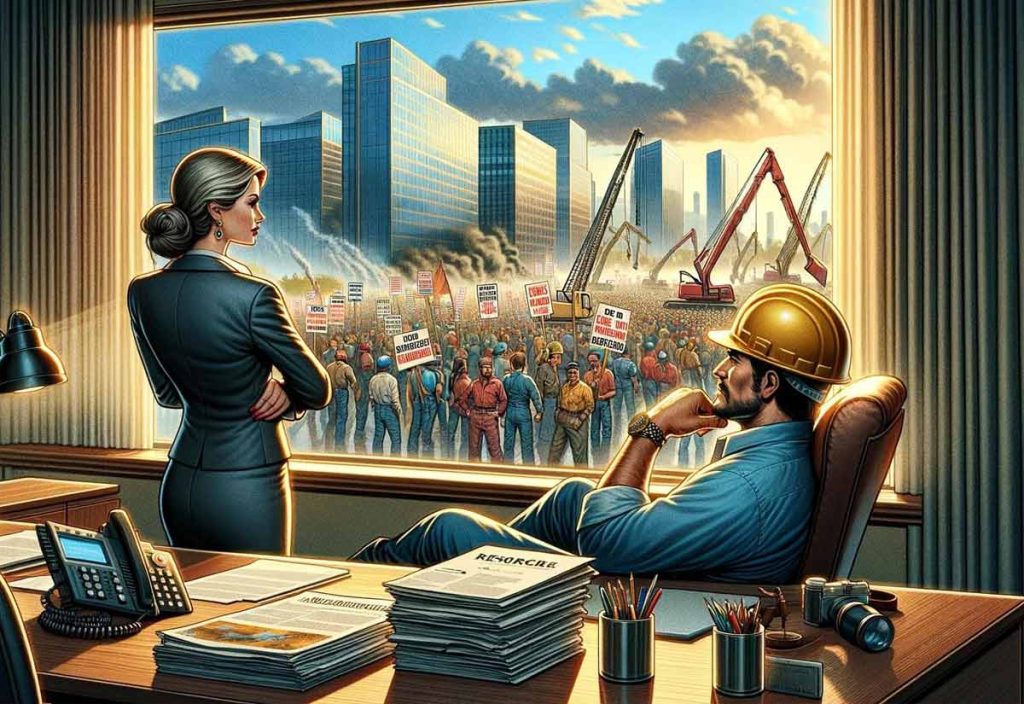

About Resource Erectors

Resource Erectors is at the heart of this heavy industry transformation in 2023 and beyond. . We specialize in recruiting and connecting talented professionals with the industry leading companies seeking their experience and talents in civil engineering, mining, energy, industrial minerals, aggregates, and construction and bulk materials handling.

Decades of specialized recruiting experience eliminates the hazards of a bad hire and helps our company clients avoid the high costs of essential vacancies in their industrial operations. When it’s time to move your company or career up the ladder in the heavy industry sector it’s time for Resource Erectors so don’t hesitate to reach out to CEO Dan so we can all get to work.