“All energy-producing machinery must be fabricated from materials extracted from the earth. No energy system, in short, is actually “renewable,” since all machines require the continual mining and processing of millions of tons of primary materials and the disposal of hardware that inevitably wears out. Compared with hydrocarbons, green machines entail, on average, a 10-fold increase in the quantities of materials extracted and processed to produce the same amount of energy.” – Mark P. Mills- Manhattan Institute

Pumped Up Demand For Mining in 2022 and Beyond

For the mining industry that 10-fold demand spike brings an increased value of metals and minerals. That changes the risk-reward equation dramatically.

Mining leftovers once considered “low-grade” resources not worth pursuing in the fossil fuel economy are now approaching precious metal status in the new green economy. Lithium mine re-openings are a case in point, where a 300% increase in global demand over the next ten to fifteen years is a conservative estimate. – Lithium Still a Valued Source, Encouraging Old Mines to Re-Open: ThermoFisher Scientific

Whether the global “net-zero” movement is “magical thinking” as Mark Mills of the Manhattan Institute suggests or not, is beside the point now. The mining industry supplies what the world demands and universal political pressure demands green energy and the enormous tonnage of earth-mined resources such an agenda will consume.

To meet that demand in risky environments the mining industry is already…

Pumping it Up! Dewatering Operations in Underground Mines

“Mines throughout Arizona have met the challenges of dewatering workings through aggressive pumping systems.”- William Ascarza Special to the Arizona Daily Star

Whether it’s coal, copper, silver, or gold, the challenges of underground mining to meet exploding demand can only be met by advanced pumping technology in modern mine operations.

Even in arid Arizona underground water sources that miners must deal with to maintain continuous extraction are abundant including:

- Meteoric water from rain, snow, and fog. Precipitation originates at the surface, working its way down to the mine through porous or fissured rock masses, alluvial material (loose clay and sediments), sand, gravel, and limestone.

- Connate water is trapped in the pores of the rocks that contain it

- Magmatic water, also known as “juvenile water” among the geology crowd, is brought from great depths to the earth’s surface by the upward shift of intrusive igneous rocks.

Diving Deeper With Deep Well Turbine Pumps

“Deep Well turbine pumps receive constantly increasing application to the problem of mining water and other fluids from great depths. Many installations of medium settings are presently operating successfully and it is felt that much greater depths are immediately within reach. Settings and lifts in excess of 2000 feet are not at all out of reason with present knowledge, experience, and materials; however, conditions of individual applications will govern in each case and dictate methods and possibilities to the designer.” – 911 Metallurgist: Deep Well Turbine Pumps

So how deep is deep and what is the depth of the “medium settings” that the article refers to? Deep well turbine pumping has an illustrious history in Arizona where the Magma Mine installed and operated a 1,200-gallon-per-minute pumping station at the 3,600-foot level.

Heavy Cornish pumps were deployed at mines in Tombstone, Arizona to cope with flooding in the 1880s. These pumps featured the largest steam-powered engines of their time, and the Cornish pump from the Iron Mountain, MI mine located on the Eastern Menominee Iron Ore Range is still the largest steam-driven pumping engine in the United States.

2 decades later two 1,500-gallon-per minute pumps were installed at the 700-foot station in the Tombstone mine to dispose of more than 2 million gallons of water daily. Arizona’s Old Dominion Mine bored holes with deep-well turbines to remove water from the mine levels to allow further development.

So we’ve seen mining pumps advance from steam to electric and that begged the question. What’s next for mine dewatering innovation as the modern mining sector expands old operations into further development?

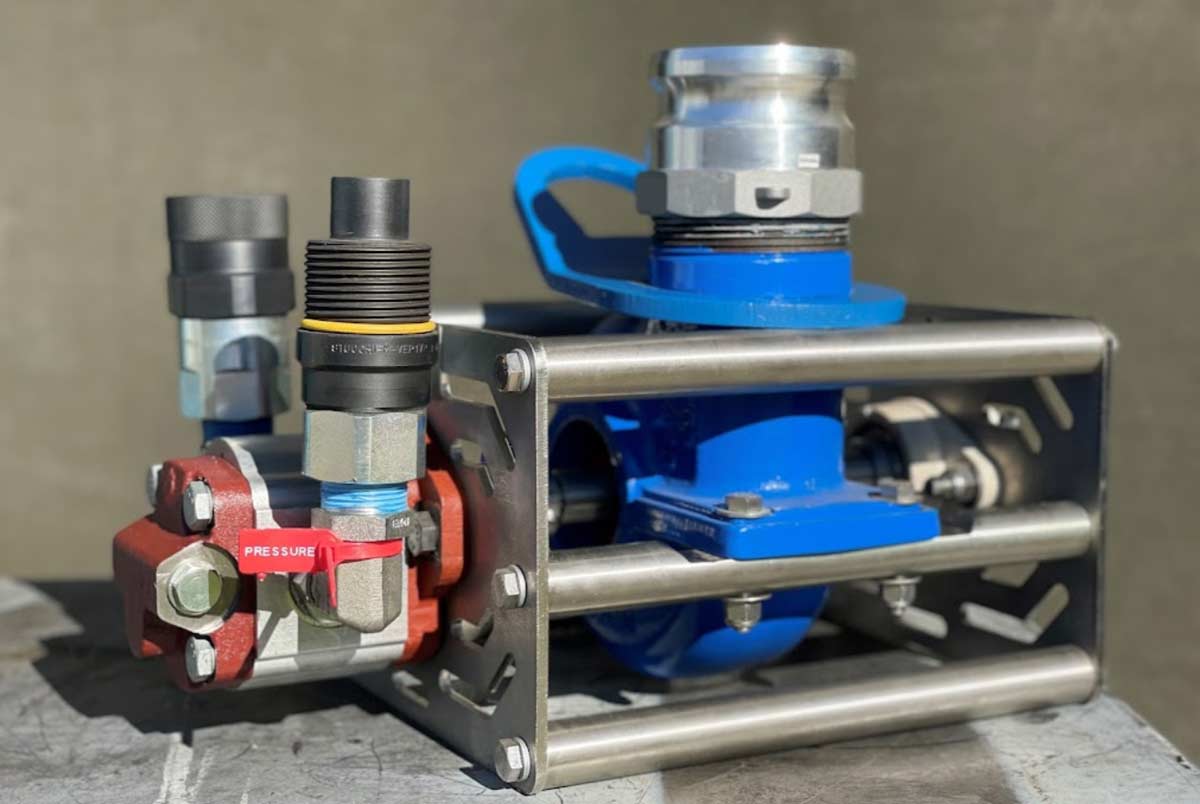

Hydraulic Pumps and the Coal Mine Reliability Test

Hydraulic mining pumps offer an alternative to submersible electric types, and one company that produces them has put their pumps to the “ coal mine reliability test.

Fast Flow Pumps aren’t subject to MSHA approval so they can be deployed on-demand without delay, just one of many operational benefits in safety and reliability that Fast Flow Pumps offer according to the company website.

- An electric power source is not required. This eliminates the hazards of operating a 3-phase 480-volt pump while standing in pools of water.

- Can be powered with existing hydraulics.

- Able to handle coal fines (tailings) and heavy mud without clogging.

- A 26 lb Pump can move up to 600GPM.

- Weighs 80% less and can pump 2.5 times the water of an electric submersible pump.

Dewatering is just one of the “daunting challenges” to be overcome by the mining sector. Resource Erectors will be keeping an eye on engineering developments that the expanding mining industry will need to overcome the challenges of safe ventilation, acidity, and the traditional mining hazards of blackdamp and firedamp.

About Resource Erectors

We bring decades of specialized human resource experience recruiting for the mining industry and more so your company can eliminate the high costs of vacancies in key positions in your organization. Our expertise at matching the top qualified professionals with heavy industry companies helps you avoid the costs and workforce disruptions of a bad hire. Over 85% of Resource Erectors candidates are still contributing to the success of their organizations 5 years later and counting.

If you’re an experienced heavy industry professional at the top of your game in mining, engineering, manufacturing, construction materials, concrete, aggregates, gypsum, bulk materials, and more, we’ve got positions available now with competitive salaries and benefits commensurate with your highly valued skill and talents. Recruiting for the companies who realize that their human resources are among their most precious resources is the key to our success and yours.

Don’t hesitate to Contact Resource Erectors today when it’s time to build or join your next heavy industry dream team.