Underground Mining Will Always Be a Challenge-Part 2

As the global economy transitions to the brave new “green giant” economy, demand in 2022 for underground mined resources is skyrocketing. Many heavy industry engineers are estimating that global demand for essential MMM, (Mined Metals and Minerals) will increase by a factor of at least 10 in this decade.

If ambitious 2030 “green benchmarks” for a “net-carbon zero” world are to be met, aggressive innovation to overcome the unavoidable challenges of underground mining, now on an unprecedented production scale is an industry priority.

In Part 1 we took a dive into dewatering, historically a major challenge in underground mining operations. Now we’ll look at some other hazards faced throughout the history of mining, and how engineers can overcome them with the innovative technology of the 21st Century to meet the challenges of unprecedented global mineral demand.

World Demand For Minerals and Risk-Reward For the Mining Industry

“World population is growing faster than at any time in history, and mineral consumption is growing faster than [the] population as more consumers enter the market for minerals and as the global standard of living increases.” – Mineral Supply and Demand into the 21st Century- USGS

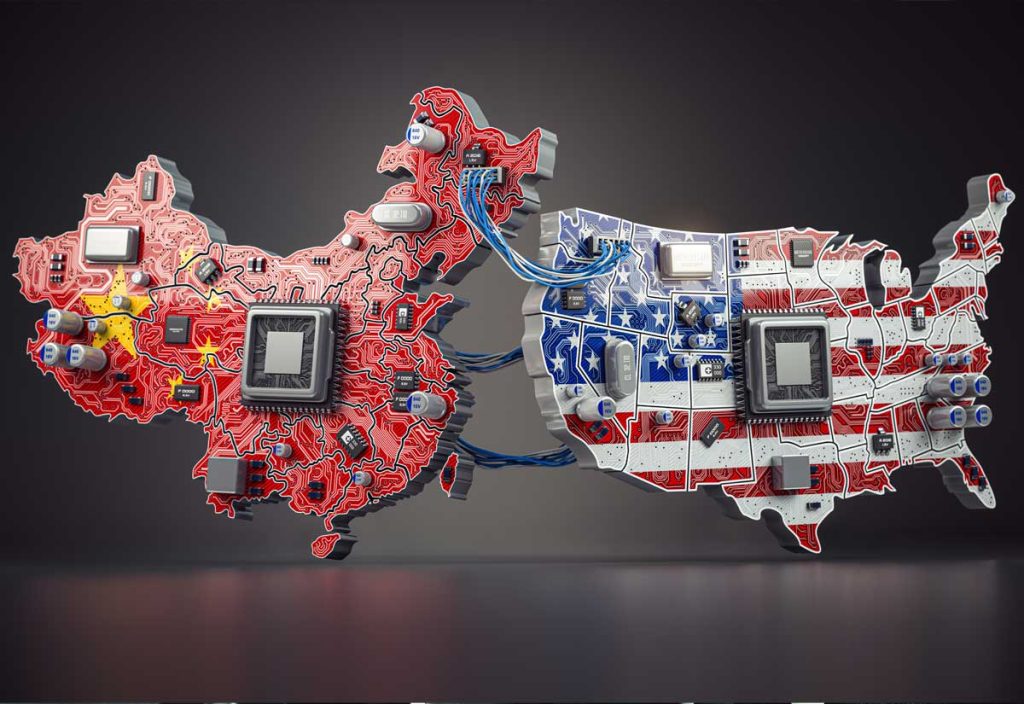

According to the United States Geological Survey document at the link above, the spike in mineral demand will be influenced by three factors:

- New and traditional uses for mineral commodities.

- The level of the world population that will consume these mineral commodities.

- The rising standard of living will determine just how much each person consumes.

The good old days of the 20th Century when a few designated “precious metals” could claim membership in that elite category may become obsolete as per capita consumption of essential minerals always outpaces population growth.

In such a case, every mined mineral becomes more “precious” as the mining industry races to keep pace with the world’s steadily increasing population and the expanding consumption that comes with it.

In Stephen E. Kesler’s informative paper for the USGS, the example of strontium is offered as a case in point. New applications for any mineral can be major game-changers in the MMM sector. When it was discovered that strontium was a most cost-effective material for preventing potentially hazardous radiation emissions from color TV tubes in the 1960s a wave of exploration and investment was the result.

The rising standard of living factor also puts traditional metals and minerals in what might be called “the soon-to-be-precious metals” category. The schematic illustration for steel consumption in the 20th Century alone is the textbook definition of a commodity spike. World steel consumption soared from about 25 million metric tons in 1900 to over 800 million by the year 2000.

Copper is another example, as new applications caused per-capita consumption to increase from about 2,000 tons to nearly 2,500 tons in just 3 decades, the years between 1970 and 2000. Graphite, lithium, and cobalt production is predicted to increase by nearly 500% to meet escalating demand according to a 2020 World Bank Group report, thanks to new EV and green energy applications.

“The transition to a net-zero economy will be metal-intensive. As the move toward cleaner technologies progresses, the metals and mining sector will be put to the test: it will need to provide the vast quantities of raw materials required for the energy transition.”- The raw-materials challenge: How the metals and mining sector will be at the core of enabling the energy transition- McKinsey and Company

Here at Resource Erectors, we’ve also witnessed the platinum/palladium competition in the traditional precious metals sector. Auto manufacturers require it for catalytic converters to meet green emissions standards that have already accelerated consumption of both essential metals. In our November 2019 article, Nanotechnology Increases Platinum and Palladium Performance new applications made platinum and palladium more precious than ever.

According to McKinsey and Company- “Metals and mining companies will be expected to grow faster, and more cleanly, than ever before.”

So we’ve talked about the demand challenges. Now let’s look at two “faster, cleaner” innovations that the mining industry is developing and deploying to meet those challenges.

VOD- Ventilation on Demand to Meet Demand

“These systems allegedly reduce the total air requirements of mines by directing air only to where it is needed, when it is needed, and reducing energy consumption in the process.”- 5 key innovations in mining ventilation- Mining Technology

As the mining industry shifts into overdrive ventilation innovations range from VOD systems that can be integrated with personnel tag and tracking systems to the use of fractured rocks to improve cooling and air delivery in underground mines.

Industry-leading companies with household names in heavy industry such as ABB, Simsmart, and Bestech are all offering versions of VOD software. According to the Mining Technology report a VOD system “that can automatically dictate airflow speed, temperature and direction has huge cost-cutting potential.”

Thermal Management in Underground Mines

Then there’s thermal management, and a concept that epitomizes the “everything old is new again” spirit of mining innovation built on hard-earned underground miner experience.

In Canada, the Mining Innovation, Rehabilitation and Applied Research Corporation (MIRARCO) teamed with organizations including Vale, Teck, and Laurentian University to work on the Natural Heat Exchange Engineering Technology (NHEET) research project.

About 50 years ago miners at Vale’s Creighton nickel mine near Sudbury, Ontario, observed that cool air was making its way into the mine in summer while warm air found its way in during the winter. The source was air trapped in the fractured waste rock of the mine. Work could be conducted at depths of 2.5 km without the use of artificial refrigeration.

The NHEET project seeks to replicate the naturally occurring thermal conditions of the Creighton mine, eliminating the high capital expenses of refrigeration and heating systems, while reducing the overall energy consumption of the mining operation.

About Resource Erectors

At Resource Erectors we specialize in recruiting and placement of the top qualified professionals for our industry-leading companies. We have open positions with competitive salaries in mining, manufacturing, aggregates, concrete, civil construction, industrial and bulk materials, engineering, and more. We bring decades of heavy industry human resource experience to the table. When it’s time for you to join or build your next heavy industry dream team don’t hesitate to contact Resource Erectors today and we can all get to work.